A Watt Governor is a type of centrifugal governor used in steam engines to regulate speed by controlling the fuel supply. It was invented by James Watt and is one of the earliest mechanical governors. The working principle of the Watt governor is based on centrifugal force, which varies with engine speed.

The governor consists of two rotating balls (masses) attached to arms, which move outward or inward as the engine speed changes. This movement is used to adjust the throttle valve, thereby regulating the fuel or steam supply and maintaining a constant engine speed.

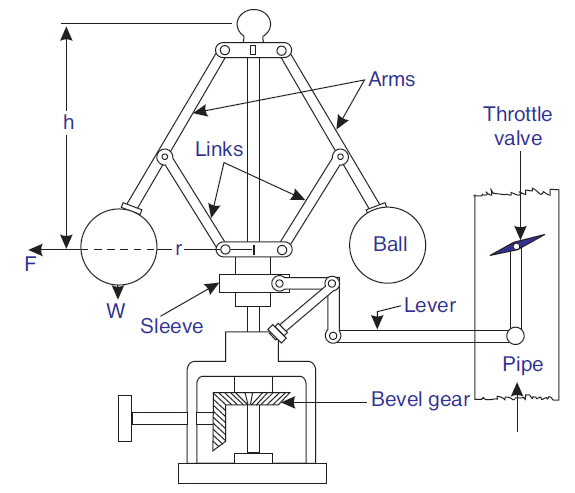

Parts of Watt Governor

The Watt Governor consists of several key components, each playing a crucial role in its operation:

1. Balls (Masses)

- Two metallic balls are attached to the arms.

- They rotate with the governor and experience centrifugal force.

- Their position determines the opening or closing of the throttle valve.

2. Arms

- Two arms connect the balls to the central spindle.

- They are free to pivot and move outward/inward with the balls.

3. Links

- Links connect the arms to the central spindle.

- They transfer motion from the balls to the sleeve.

4. Sleeve

- A movable sleeve is mounted on the central spindle.

- It moves up or down based on the balls’ movement.

- The sleeve’s position determines the throttle valve’s opening.

5. Spindle (Vertical Shaft)

- A vertical shaft that rotates with the engine.

- It carries the arms, links, and sleeve.

- The rotation of the spindle controls the governor’s operation.

6. Bevel Gear Mechanism

- The spindle is connected to the engine through a bevel gear.

- This ensures that the governor’s speed is proportional to the engine speed.

7. Lever Mechanism

- The lever connects the sleeve to the throttle valve.

- It helps in adjusting the fuel supply based on the governor’s movement.

8. Throttle Valve

- A valve in the fuel or steam supply line.

- It opens or closes depending on the governor’s sleeve position.

- Regulates the engine speed by controlling the fuel flow.

Working Principle of Watt Governor

The Watt Governor operates on the centrifugal force principle. The rotation of the governor is directly linked to the engine shaft through a bevel gear mechanism. When the engine speed increases, the balls move outward due to centrifugal force, raising the sleeve and adjusting the throttle valve to reduce fuel supply. Conversely, when the speed decreases, the balls move inward, lowering the sleeve and increasing the fuel supply.

Step-by-Step Working Mechanism

- Normal Speed Condition: At a constant engine speed, the balls maintain a fixed radius, keeping the throttle valve steady.

- Increase in Engine Speed: When the engine speed increases, the centrifugal force acting on the balls increases. The balls move outward, lifting the sleeve. This movement actuates the lever mechanism, reducing the throttle valve opening. Fuel supply decreases, reducing the engine speed back to normal.

- Decrease in Engine Speed: If the engine speed decreases, the centrifugal force acting on the balls reduces. The balls move inward, lowering the sleeve. This movement opens the throttle valve more. The increased fuel supply raises the engine speed back to normal.

Thus, the Watt Governor helps in automatic speed regulation of the engine.

Advantages of Watt Governor

The Watt Governor offers several benefits in engine speed control:

- Simple Construction: The Watt Governor is mechanically simple and easy to manufacture.

- Automatic Speed Regulation: It automatically adjusts the fuel supply to maintain a constant engine speed.

- Reliable Operation: It provides smooth and stable operation without requiring external control.

- No External Power Required: Works purely on centrifugal force without electrical or hydraulic power.

- Energy Efficient: Helps in maintaining efficient fuel usage by preventing unnecessary fuel supply.

- Suitable for Low-Speed Engines: It is highly effective for slow-speed engines (below 200 RPM).

- Low Maintenance: Since it has fewer moving parts, maintenance costs are low.

Applications of Watt Governor

The Watt Governor is widely used in various mechanical and industrial applications:

- Steam Engines: Primarily used in steam engines to regulate speed automatically.

- Small Power Plants: Used in small-scale power plants to maintain constant generator speed.

- Textile Mills: Used in textile machines to maintain uniform motion and prevent speed fluctuations.

- Industrial Machinery: Applied in various mechanical machines that require speed regulation.

- Locomotives: Early steam locomotives used Watt governors to maintain stable speeds.

- Agricultural Machinery: Used in water pumps, grain mills, and other agricultural machines to prevent overspeeding.

Disadvantages of Watt Governor

Despite its advantages, the Watt Governor has some limitations:

- Limited to Low Speeds: It is only suitable for slow-speed engines (below 200 RPM). At higher speeds, its control becomes inefficient.

- Less Responsive: Response time is slower compared to modern governors.

- Affected by Load Variations: Sudden load changes can affect its stability.

- Mechanical Wear: Moving parts experience mechanical wear over time.

- Not Suitable for High-Speed Engines: High-speed engines require more advanced governors like Hartnell or Wilson-Hartnell governors.

Conclusion

The Watt Governor is a fundamental speed-regulating device in steam engines and other mechanical systems. Its simple design, automatic operation, and reliability make it a preferred choice for low-speed applications. However, its limitations in high-speed applications have led to the development of more advanced governor systems.