A Tomlinson Surface Meter is a mechanical instrument used to measure the surface roughness of a material. It operates by tracing the profile of the surface with a stylus and amplifying the vertical displacement, which is then recorded as a trace on smoked glass.

This instrument is widely used in metrology and quality control to ensure that manufactured components meet required surface finish standards.

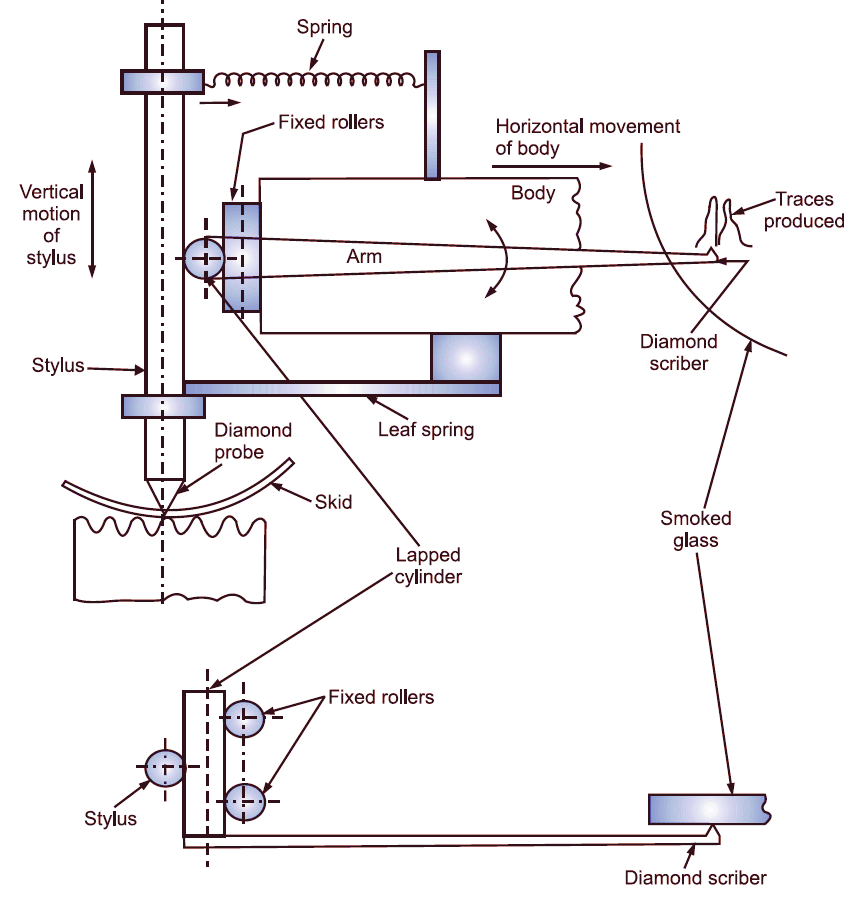

Parts of a Tomlinson Surface Meter

The Tomlinson Surface Meter consists of several key components that work together to amplify and record surface deviations:

- Stylus: A diamond-tipped probe that moves over the test surface. Detects even minor surface irregularities.

- Diamond Probe: A specialized fine-tip probe that ensures precise contact with the surface.

- Skid: A reference support that maintains steady movement. Helps eliminate errors due to unwanted lateral motion.

- Arm & Body: The arm transfers motion from the stylus to the scriber. The body houses the internal mechanism.

- Fixed Rollers: A set of precision rollers that guide the movement of the system. Reduces friction and ensures smooth displacement.

- Spring Mechanism: A spring maintains tension and helps control movement. Ensures the stylus stays in contact with the surface.

- Leaf Spring: Helps in mechanical damping, preventing unwanted oscillations.

- Lapped Cylinder: A high-precision cylinder that supports the movement system.

- Diamond Scriber: A diamond-tipped marking tool that records the amplified movement. Produces traces on smoked glass for visual analysis.

- Smoked Glass: A recording surface where the roughness profile is traced. The trace represents peaks and valleys of the measured surface.

Working Principle of Tomlinson Surface Meter

The Tomlinson Surface Meter works on the principle of mechanical amplification. The stylus follows the surface irregularities, and these minute vertical displacements are transferred through a system of levers and rollers, which then produce an amplified trace on a smoked glass.

- A diamond stylus moves over the surface irregularities.

- The vertical movement of the stylus is transferred to a pivoted arm.

- A diamond scribe at the end of the system records the movement onto smoked glass.

- The resulting trace represents the surface roughness profile.

This mechanical system allows for high sensitivity, making it effective for detecting even minor deviations in surface texture.

Working of Tomlinson Surface Meter

- The stylus is placed in contact with the surface to be measured.

- As the instrument moves, the stylus moves vertically due to surface irregularities.

- The vertical displacement is transferred to the pivoted arm.

- The arm, through a system of levers, rollers, and springs, amplifies the movement.

- The diamond scriber at the other end of the arm traces this movement onto smoked glass.

- The resulting trace provides a visual representation of surface roughness.

The final output is an enlarged roughness profile, which can be analyzed to determine parameters such as Ra (average roughness), Rz (mean peak-to-valley height), and Rt (total roughness height).

Advantages of Tomlinson Surface Meter

- Highly Accurate for Surface Roughness Measurement: Capable of detecting very fine irregularities.

- Mechanical Operation (No Electronics Required): Works in environments where electronic instruments may not be suitable.

- Reliable and Robust: Simple, durable construction ensures long-term usability.

- Produces a Permanent Record: The trace on smoked glass can be stored for reference.

- Cost-Effective: Compared to modern digital profilometers, it is a more economical solution.

- No Electrical Interference: Since it is fully mechanical, it is immune to electromagnetic interference.

Applications of Tomlinson Surface Meter

- Quality Control in Manufacturing: Ensures that machined parts meet required roughness specifications.

- Metrology and Precision Engineering: Used in research and calibration of other roughness measurement devices.

- Aerospace and Automotive Industry: Ensures critical components have the required surface finish for optimal performance.

- Tool and Die Making: Checks surface smoothness in high-precision tool manufacturing.

- Material Science and Research Helps in studying material surface properties and their effects on performance.

- Inspection of Bearings and Shafts: Verifies surface roughness to prevent premature wear and failure.

Disadvantages of Tomlinson Surface Meter

- Limited to Small Surfaces: Not suitable for measuring large or complex geometries.

- Time-Consuming: Requires careful setup and interpretation of traces.

- Manual Interpretation Required: Unlike digital instruments, results need expert analysis.

- Fragile Recording Medium: Smoked glass traces can be easily damaged or erased.

- Not Suitable for Soft Surfaces: The diamond stylus may leave marks on delicate materials.

Conclusion

The Tomlinson Surface Meter is a highly accurate and reliable mechanical instrument for measuring surface roughness. It is widely used in quality control, manufacturing, and research where precision surface measurements are essential.