A throttling calorimeter is a device used to measure the dryness fraction (quality) of steam. It operates on the principle of throttling expansion, where high-pressure steam undergoes an adiabatic expansion through a throttling valve, leading to a drop in pressure and a rise in entropy. This enables determining the dryness fraction of steam by measuring the temperature and pressure after throttling.

Working Principle of Throttling Calorimeter

The working of a throttling calorimeter is based on the throttling process, which is an isenthalpic process (constant enthalpy process). When wet steam at high pressure passes through a throttling valve, it expands suddenly, causing the steam to become superheated or approach a drier state. The dryness fraction of steam is then calculated based on the temperature and pressure measurements after expansion.

The key thermodynamic concepts involved in the working principle are:

- Throttling Process (h₁ = h₂): The enthalpy before and after expansion remains constant.

- Superheated Steam Condition: If the steam becomes superheated after throttling, its properties can be used to determine the initial steam quality.

- Dryness Fraction (x): If the steam remains wet after throttling, additional calculations are required to find the exact quality of steam.

Mathematical Expression for Dryness Fraction

The dryness fraction \( x \) can be determined using the enthalpy equation:

\[

h_1 = h_2

\]

For wet steam:

\[

h_1 = h_f + x h_{fg}

\]

For superheated steam after throttling:

\[

h_2 = h_g + C_p (T_2 – T_g)

\]

By equating these:

\[

h_f + x h_{fg} = h_g + C_p (T_2 – T_g)

\]

Solving for \( x \):

\[

x = \frac{h_g + C_p (T_2 – T_g) – h_f}{h_{fg}}

\]

where:

\( h_f \) = Enthalpy of saturated liquid at initial pressure

\( h_{fg} \) = Latent heat of vaporization

\( h_g \) = Enthalpy of dry saturated steam

\( C_p \) = Specific heat capacity of superheated steam

\( T_2 \) = Superheated temperature after throttling

\( T_g \) = Saturation temperature at final pressure

Parts of a Throttling Calorimeter

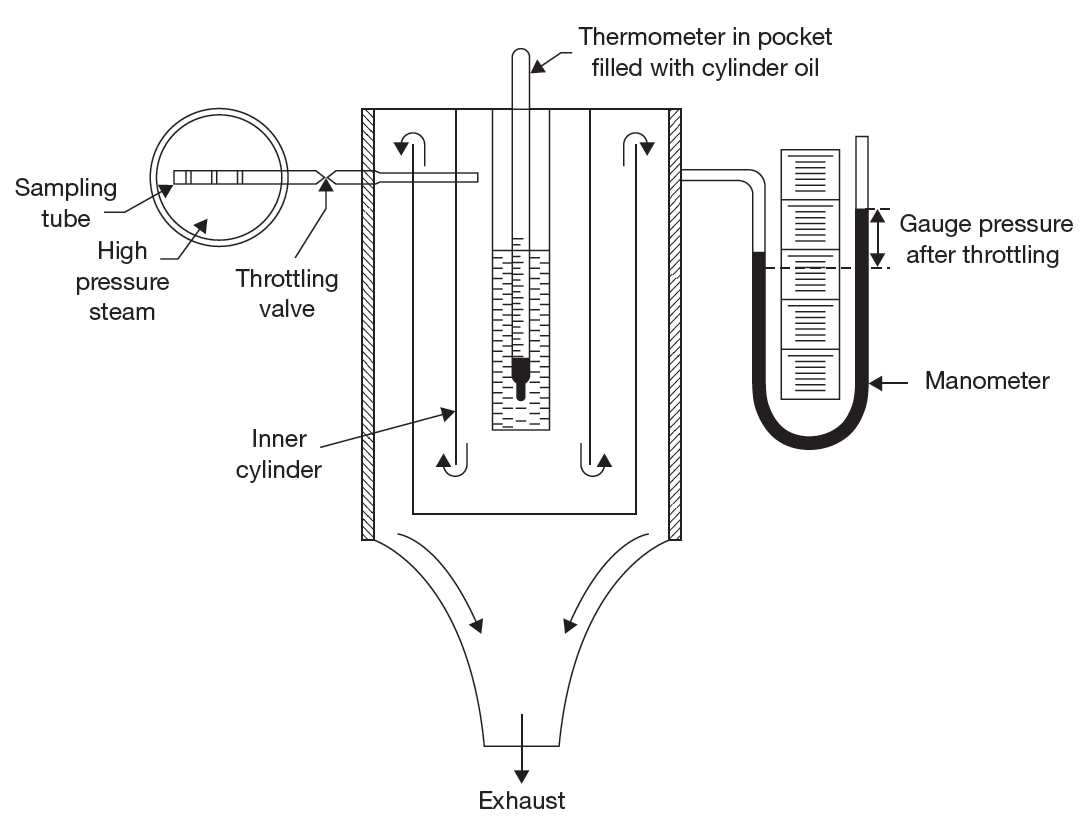

A throttling calorimeter consists of the following main components:

- Sampling Tube: Extracts a sample of steam from the steam pipeline. Ensures that the steam entering the calorimeter is representative of the overall system.

- Throttling Valve: A narrow orifice or valve that allows high-pressure steam to expand suddenly. It causes the pressure drop and leads to superheating (if conditions are met).

- Inner Cylinder: The chamber where the throttling expansion occurs. Ensures proper mixing and expansion of steam before measurement.

- Thermometer (Pocket Filled with Cylinder Oil): Measures the temperature of steam after expansion. The pocket filled with cylinder oil helps stabilize temperature readings.

- Manometer: Measures the pressure after throttling. Helps determine steam properties after expansion.

- Exhaust Outlet: Allows the expanded steam to exit after measurement. Ensures continuous flow through the calorimeter.

Advantages of Throttling Calorimeter

- Simple and Accurate: Provides a reliable method to determine steam quality.

- Requires Minimal Equipment: Uses only a throttling device, thermometer, and pressure gauge for measurements.

- No Moving Parts: Increases durability and reduces maintenance costs.

- Provides Direct Superheated Steam Data: Eliminates the need for complex calculations in most cases.

- Suitable for High-Pressure Steam: Can handle high-pressure steam samples effectively.

Applications of Throttling Calorimeter

- Power Plants: Used in steam power plants to measure steam quality and improve turbine efficiency.

- Boilers and Steam Engines: Helps in determining the efficiency of boilers and steam engines.

- Industrial Processes: Used in chemical and food industries where steam is a key part of the process.

- Research and Testing Laboratories: Used in thermodynamics experiments and educational demonstrations.

Disadvantages of Throttling Calorimeter

- Not Suitable for Low-Pressure Steam: If the steam is not dry enough after throttling, the method becomes inaccurate.

- Requires Initial High-Pressure Steam: The method is effective only if the steam becomes superheated after expansion.

- Potential Measurement Errors: Temperature and pressure fluctuations can cause errors in the calculated dryness fraction.

- Limited Range of Steam Quality Measurement: If the steam is too wet before throttling, it may not become superheated, leading to invalid results.

Conclusion

The throttling calorimeter is an essential tool in thermodynamics and steam engineering, providing a simple and effective method to determine the dryness fraction of steam. While it has limitations for wet steam, its advantages make it a widely used device in industrial and research applications.