A Sigma Comparator is a high-precision mechanical comparator used to measure small linear dimensions or deviations in engineering components. It functions based on mechanical amplification principles to compare the measured dimension against a standard.

Comparators do not measure actual dimensions but indicate differences from a given standard. The Sigma Comparator is known for its high accuracy, robustness, and ease of operation.

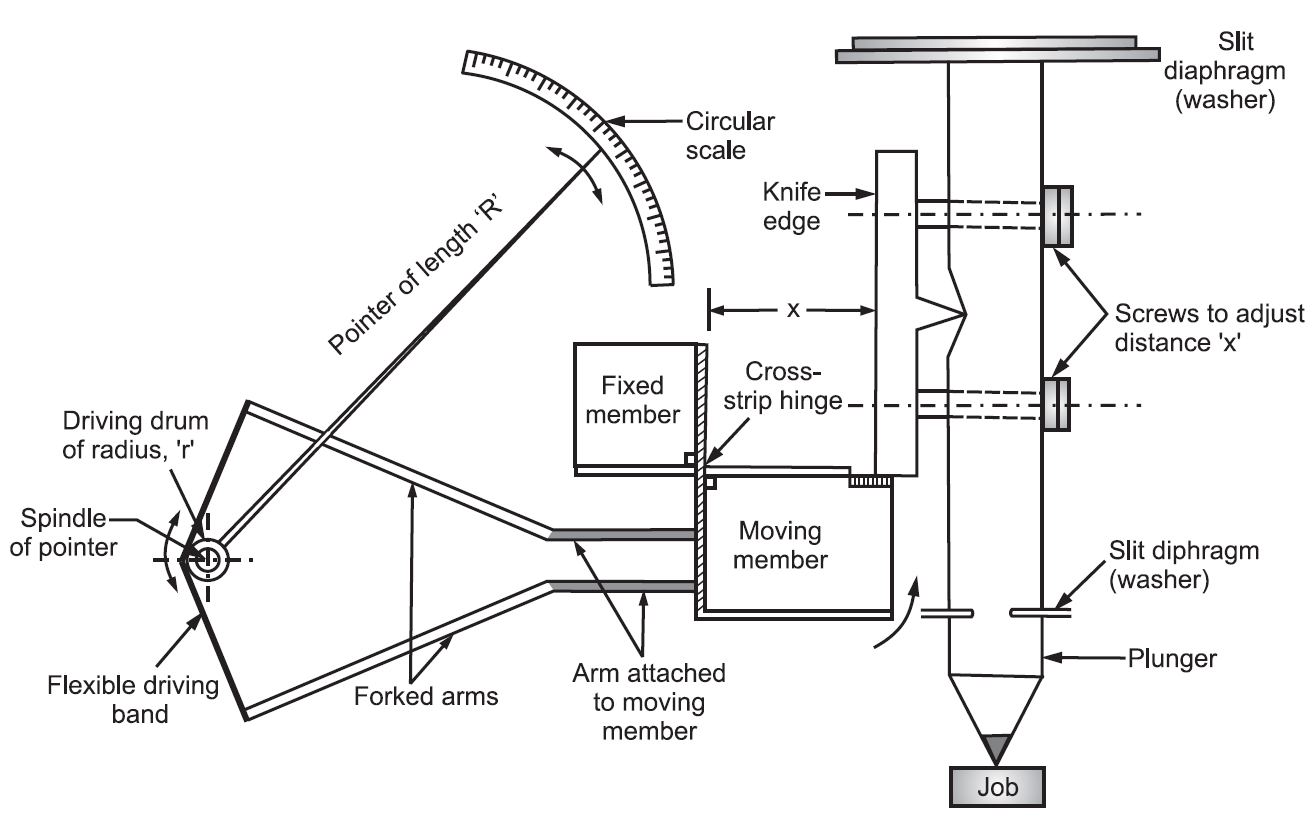

Parts of a Sigma Comparator

The Sigma Comparator consists of the following key components:

- Plunger: The plunger is the contact point with the workpiece. It moves vertically based on the variations in the measured dimension.

- Slit Diaphragm (Washer): The slit diaphragm ensures that the plunger moves smoothly without lateral displacement. It provides a controlled linear movement.

- Moving Member & Fixed Member: The moving member is connected to the plunger and transfers motion to the linkage system. The fixed member provides structural support.

- Cross-Strip Hinge: A cross-strip hinge is a flexible mechanism that allows slight movement while maintaining rigidity. It ensures smooth force transmission without introducing backlash.

- Knife Edge: A knife edge provides a precise pivot point for the moving system. It minimizes friction and hysteresis.

- Lever & Arm System: A set of levers and forked arms amplify the movement from the plunger. The system converts small linear displacement into significant angular displacement.

- Flexible Driving Band: The driving band transfers motion to the spindle without introducing backlash. It enhances measurement sensitivity.

- Pointer and Circular Scale: The pointer is attached to a spindle and moves across the circular scale. The scale is marked for precise readings of deviations.

- Driving Drum: The driving drum rotates due to the flexible band and amplifies the movement further.

- Screws for Adjustment: These screws allow for fine adjustments in distance and alignment. They help in calibration and precision settings.

Working Principle of a Sigma Comparator

The Sigma Comparator works on the principle of mechanical amplification. When a small displacement occurs at the plunger (due to the deviation of a component’s dimension), it is amplified through a system of levers, pivots, and linkages. The amplified movement is then displayed on a circular scale using a pointer.

The total amplification is given by the ratio of the pointer movement to the plunger displacement.

Mathematically, the amplification factor is:

\[

\text{Amplification Factor} = \frac{\text{Pointer Movement}}{\text{Plunger Displacement}}

\]

The primary elements contributing to this amplification include:

- Mechanical Linkages (lever arms, knife edges)

- Flexible Bands

- Pointer and Scale Mechanism

Since the system does not rely on electronic or pneumatic elements, it is highly reliable and free from electrical interference.

Working of Sigma Comparator

- The plunger contacts the workpiece (job).

- If there is a dimensional variation, the plunger moves up or down.

- The movement is transmitted to the moving member through the cross-strip hinge.

- The knife edge and lever system amplify this motion.

- The flexible driving band rotates the driving drum, causing further amplification.

- The pointer moves across the circular scale, indicating the deviation from the standard dimension.

- The reading is taken directly from the scale, providing a comparative measurement.

The entire mechanism ensures that even a small displacement of the plunger results in a large movement of the pointer, making it easy to detect minute variations.

Advantages of Sigma Comparator

- High Sensitivity: Capable of detecting minute changes in dimensions.

- No Electrical Components: Works purely on mechanical principles, making it suitable for environments with electrical interference.

- Reliable and Durable: The robust construction ensures long-term usability with minimal maintenance.

- No Backlash Errors: Due to the flexible driving band, there is no play in the mechanism.

- High Accuracy: Can detect deviations as small as 0.001 mm.

- Easy to Use: Simple setup and direct reading make it user-friendly.

- Cost-Effective: Compared to electronic comparators, the Sigma Comparator is more affordable.

Applications of Sigma Comparator

- Precision Engineering: Used for measuring small deviations in machine components.

- Quality Control in Manufacturing: Helps ensure parts are within specified tolerances.

- Inspection of Shafts and Bearings: Used in industries where high precision is required.

- Gauge Calibration: Used to compare new gauges with standard references.

- Metrology Labs: Used for research and high-precision measurements.

- Automobile and Aerospace Industry: Ensures components fit within strict tolerances.

- Tool Room Applications: Used in tool-making processes for accuracy checks.

Disadvantages of Sigma Comparator

- Manual Reading Errors: The operator must carefully note readings to avoid parallax errors.

- Limited Range: The measuring range is restricted to small deviations.

- Requires Skilled Operators: Interpretation of scale readings requires expertise.

- Not Suitable for Large Components: Due to its design, it is best suited for small parts.

- No Digital Output: Unlike modern electronic comparators, it lacks data recording capabilities.

Conclusion

The Sigma Comparator is an essential tool in precision measurement, widely used in industries that demand high accuracy. Its mechanical amplification system provides reliable, cost-effective, and high-sensitivity measurement without electronic components.

Despite some limitations, its advantages make it a valuable instrument for quality control, tool rooms, and research laboratories. With proper handling and calibration, it remains a preferred choice for high-precision comparative measurements.