A Rope Brake Dynamometer is a mechanical device used to measure the brake power of an engine by utilizing frictional resistance created by a rope wound around a rotating drum. It is commonly used for testing the power output of engines, particularly in laboratories and workshops.

Construction of Rope Brake Dynamometer

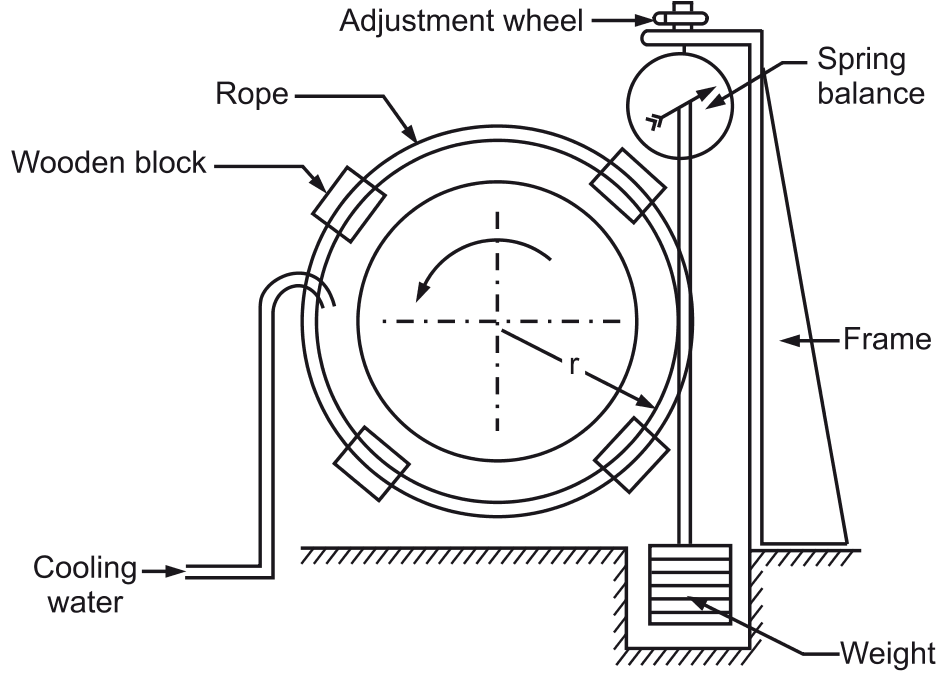

The Rope Brake Dynamometer consists of the following components:

- Brake Drum (Pulley): A rotating drum attached to the engine shaft.

- Rope: A rope is wound around the drum to create friction.

- Wooden Blocks: Placed between the rope and the drum to increase friction.

- Spring Balance: Measures the tension in the rope.

- Weight (Load): Provides a resisting force to balance the torque.

- Frame: A fixed structure that supports the setup.

- Adjustment Wheel: Used to tighten or loosen the rope.

- Cooling Water Supply: Reduces heat generated due to friction.

Working Principle of Rope Brake Dynamometer

The working of the Rope Brake Dynamometer is based on frictional resistance and torque measurement. The process is as follows:

- The engine rotates the brake drum.

- A rope is wound around the drum, with one end attached to a weight and the other connected to a spring balance.

- The friction between the rope and drum applies a braking force to the rotating shaft.

- The force exerted by the weight and the reading from the spring balance help calculate the torque exerted on the drum.

- Using the measured torque and rotational speed, the brake power of the engine is determined.

Mathematical Derivation

To determine the brake power (BP) of the engine, we use the following formula:

Torque Calculation

The effective force exerted by the rope is:

\[F = W – S\]

where:

\( W \) = Load weight (N)

\( S \) = Spring balance reading (N)

\( F \) = Net force exerted on the rope (N)

The torque applied on the drum is given by:

\[T = (W – S) \times r\]

where:

\( T \) = Torque (N\cdot m)

\( r \) = Radius of the brake drum (m)

Brake Power Calculation

The power absorbed by the dynamometer is given by:

\[BP = \frac{2\pi N T}{60}\]

where:

\( BP \) = Brake Power (Watts or kW)

\( N \) = Rotational speed of the shaft (RPM)

\( T \) = Torque (N\cdot m)

If converted to horsepower (HP):

\[BP (HP) = \frac{2\pi N T}{4500}\]

Advantages of Rope Brake Dynamometer

- Simple Design: Easy to construct and use.

- Low Cost: Requires inexpensive materials.

- Direct Torque Measurement: Provides accurate torque values.

- Portable: Can be used in different locations.

- No Need for Electronic Sensors: Works mechanically without electrical components.

Applications of Rope Brake Dynamometer

- Engine Testing: Used to measure the power output of IC engines.

- Educational Labs: Helps students understand power measurement principles.

- Agricultural Machinery: Used to test tractors and farming equipment.

- Mechanical Workshops: Employed in performance testing of rotating machinery.

- Small Motors Testing: Suitable for measuring the power of low-capacity motors.

Disadvantages of Rope Brake Dynamometer

- Heat Generation: Requires cooling water to dissipate heat.

- Frictional Wear: Continuous use causes wear of the rope and wooden blocks.

- Limited Load Capacity: Not suitable for high-power engines.

- Manual Adjustments Required: Rope tension needs to be manually controlled.

- Inefficient: Energy is lost as heat rather than being utilized effectively.

Conclusion

The Rope Brake Dynamometer is a simple and effective method for measuring the brake power of engines. While it has limitations in terms of heat generation and manual adjustments, its affordability and ease of use make it a popular choice in mechanical testing applications. It remains a valuable tool for educational and industrial purposes.