Proper planning and control of the production system is essential for efficient and economical production. Economy and Productivity are to a large extent directly proportional to the thoroughness with which the planning and control functions are performed.

Concept and Need of Production Planning

Production Planning involves management decisions relating to how much to produce, what materials, parts and tools will be needed, what steps should be followed in the production process, within what time limit the production is to be completed and how much work is to be done by each work station.

Production Planning is a production activity involving arranging facilities and designing the production system. Et is based on sales commitments as to quantity, delivery dates, price, quality, etc.

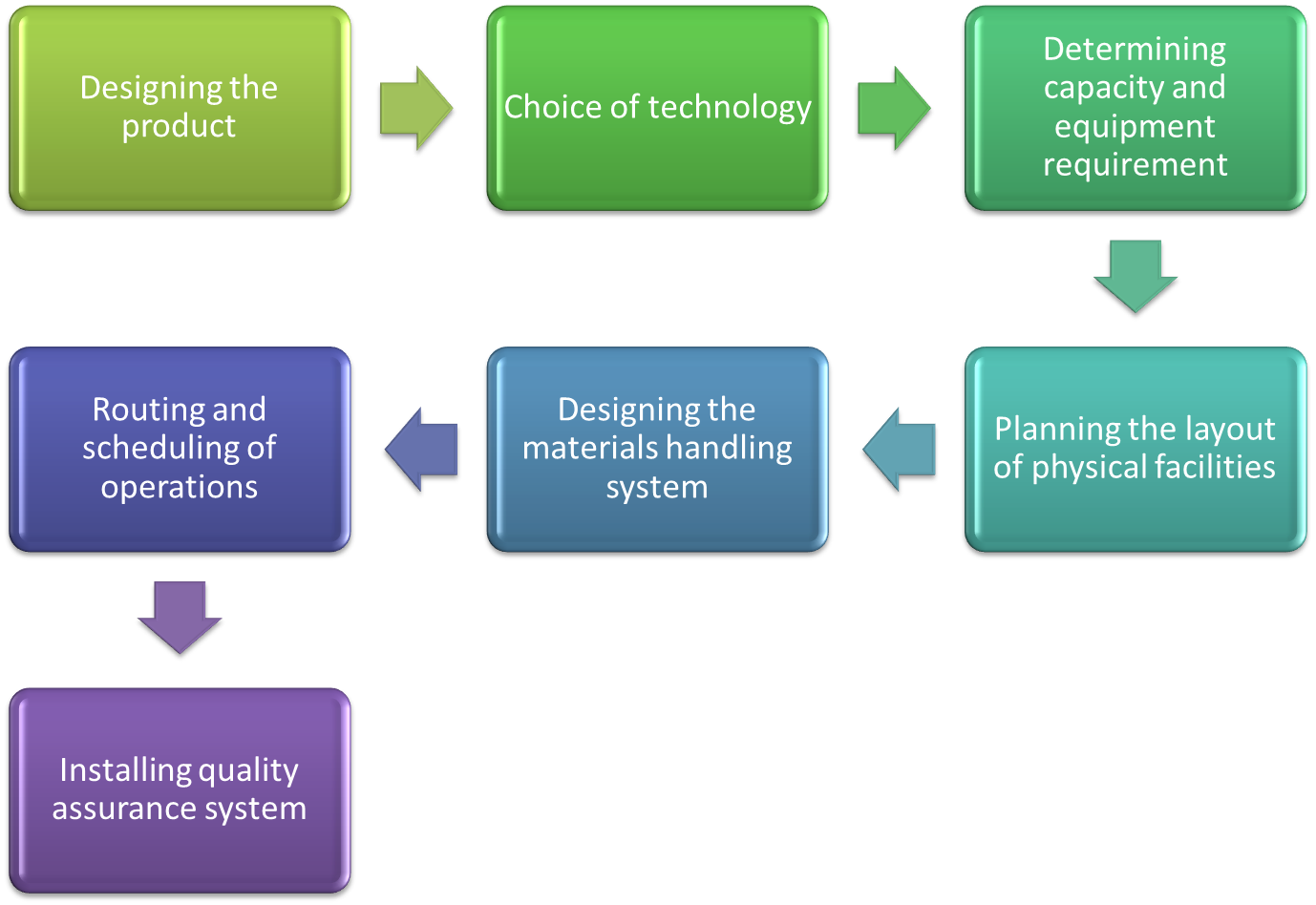

Production Planning is the ‘thinking’ phase of the production process. The main decisions required in production planning are

- Designing the product

- Choice of technology

- Determining capacity and equipment requirement

- Planning the layout of physical facilities

- Designing the materials handling system

- Routing and scheduling of operations

- Installing quality assurance system

Complex production operations, wide range of products, pressure for higher quality, growing number of suppliers, technological progress, etc., have made Production Planning a certain necessity. There is no substitute for Production Planning as lack of planning means chaos ¡n industry.

Factors Influencing Production Planning

The main factors that influence the Production Planning are as under:

Volume of Production: Volume of production depends upon market forecast and customer orders. Volume determines the degree of production planning and serves as the basis for loading and scheduling.

Nature of Production: Complex and sophisticated products require more thorough Production Planning than simple products.

Type of Production Process: In continuous manufacturing system, line balancing is necessary to avoid shutdown. On the other hand, in batch production process, effective use of installed facilities is a more significant problem.

Elements of Production Planning

The main elements of Production Planning are as Ibliows.

Estimating: The volume of production is decided through capacity planning. The product to be produced is decided on the basis of market requirements. The product design is analysed to determine the materials, tools, parts and labour requirements. A bill of materials is prepared to specify the nature and amount of materials required. Inventory levels for materials are decided and purchase requisitions are issued.

Routing: Routing is the process of determining the sequence of operations to be performed in the production process. The methods of techniques of production are decided. Routing determines what work will be done on a product or part as well as where and how it will be done. it specifies the operations to be performed. their sequence and proper types of machines and personnel required.

The objective of routing is selecting the best and the cheapest method of work.

Routing depends on the nature of machines, the efficiency of employees, the availability of physical facilities and the type of manufacturing process.

In a continuous process industry, route is standardised and fixed.

Route is the path over which materials will travel in course of their conversion into finished product.

A route sheet or route chart is a written specification of the sequence of operations. Route sheets are very helpful in guiding operations for each part.

Sequencing: Sequencing decides the operations to be performed, their order and machines on which they will be performed. Proper sequencing ensures smooth and uninterrupted flow of work.

Proper routing and sequencing also helps in minimising delays, wastage and materials handling costs.

With the help of proper plant layout, sound materials handling system and an integrated routing plan, the firm can avoid multiple handling, delays, criss-crossing and bottlenecks etc.

Manufacturing Lead Time

It is the time interval required from the date of receiving a customer order upto the date of despatch of finished products. It can be determined by estimating in detail the time involved in processing of order, preparing the work order communicating lo the shop floor, withdrawal of materials from stores, processing of materials and allowances for any unexpected interruptions, etc.

Accurate estimation of lead time is very essential just in time (JIT – Japanese System) manufacturing. PERT/CPM network planning technique can be used where the order represents, a long duration of manufacturing spread over several months.

Scheduling: Scheduling involves fixing priorities for different jobs and laying down the starting and finishing dates for each job. It involves the preparation of a time table which would indicate the total time needed for the manufacture of a product as also the time expected to be spent on each machine or operation.

A production schedule specifies when each operation is to be carried out. The objective of scheduling is to issue coordinated schedules to the plant so that product ¡s manufactured by the delivery date planned by the sales department. Lack of information regarding existing workload, lead time, manufacturing time is the main obstacle in good scheduling.

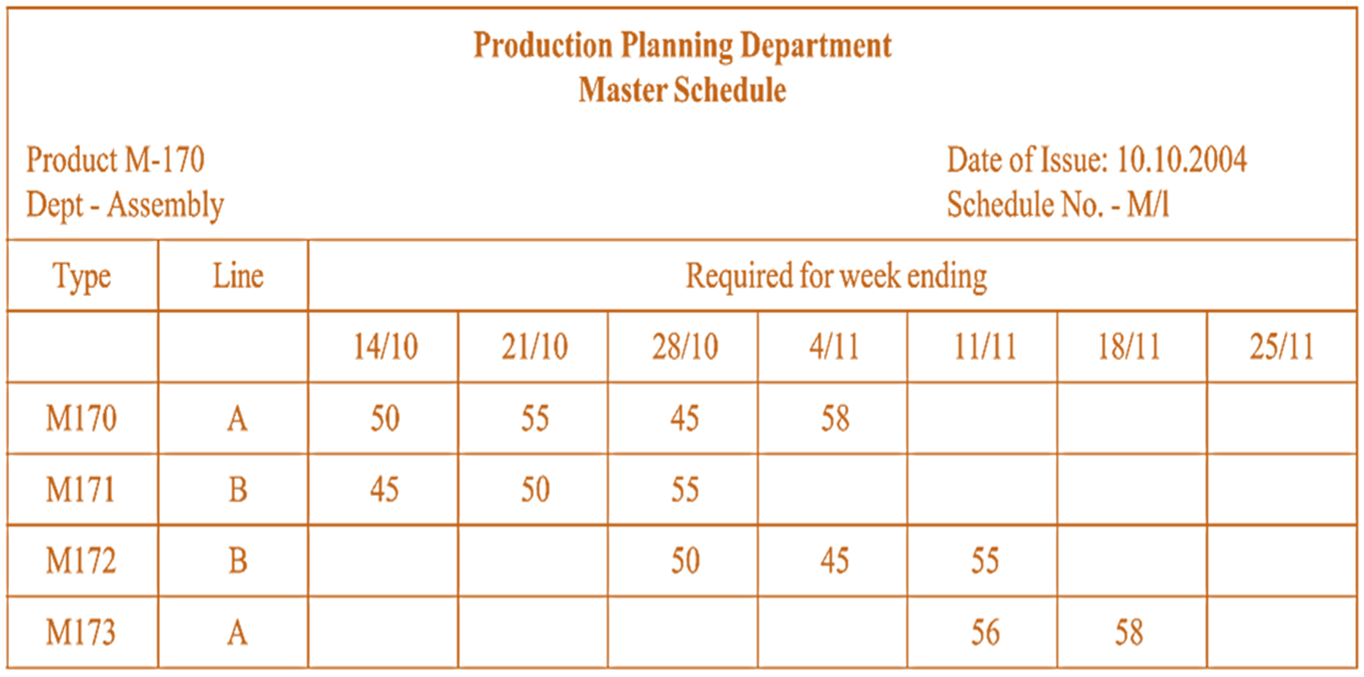

Scheduling begins with the preparation of master schedule which represents the overall production programme of the plant for a given period of time. It indicates the dates on which the various jobs have to be completed. Master schedule is prepared on the basis of sales forecast, schedule. route programme of the plant for a given period of time. It indicates the dates on which the various jobs have to be completed. Master schedule is prepared on the basis of sales forecast, schedule, route sheet, loading chart and promised delivery

The Gantt chart type master schedule is vely popular as it facilitates both planning and follow-up of the progress of work. A sample master schedule is given below:

From the master schedule, detailed shop, departmental and daily operation schedules are prepared. These schedules help to implement the master schedule. Shop and departmental schedule should be integrated into the master schedule as planned.

In order to ensure coordination, controls must be established at critical points. These controls are accomplished in the detailed schedules for shops and departments.

Thus, three types of schedules are required for scheduling:

- Master Schedule. It is the aggregate schedule indicating the elates on which various jobs are to be completed.

- Department Schedule. It fixes the time period within which a particular work or operation is to be completed.

- Daily Operation Schedule. It indicates the time required to pcrfòrrn each detailed operation on a given job.

Preparation of production schedule takes into account several factors.

- Various job schedules.

- Production capacities and operating efficiencies of various departments.

- Maintenance schedule.

- Orders already in progress.

- Possible holidays, interruptions and absenteeism.

- Availability of raw materials.

Effective scheduling is essential for efficient production. It helps to meet delivery commitments, to balance production loads, to minimise inventory level and to maximise utilisation of man and machines. Master Production Schedule serves the basis of manufacturing plan.

Facility Loading: Loading means the assignment of specific jobs to specific machines for the purpose of completing each operation by the specified date. Loading is the process of converting operation schedule into practice.

Scheduling gives the estimated date for completion of work whereas loading determines the feasibility of these dates.

Available capacity should be fully utilised in loading. Steps involved in loading a machine or other facilities are as follows:

- Find Out the estimated time to perform each operation.

- Find out the availability of various machines.

- Identify the earliest date when the required hours can be utilised on a given machine.

- Schedule bottleneck operation and schedule subsequent operations as early as possible consistent with route sheet

Types of Production Planning

There are two types of Production Planning:

Long-range Planning: It focuses on the utilisation of production facilities in the long run to achieve organisational objectives. It is strategic in nature. It takes into account the investment capacity, product life cycles, technology level, market requirement, etc. It is technically called Capacity Planning.

Crude Petroleum Refining Plants use long-range planning technique, since the products, demand is uniform throughout the year and do not vary from seasons to seasons.

It lays down the following objectives:

- Product volume

- Operating capacities

- Inventory policies

- Delivery policy and programme

- Maintenance policy and programme

- Level of manufacturing cost

Short-term Planning: It is operational planning concerned with the utilisation of existing facilities rather than with the creation of new facilities. It is tactical in nature.

Usually, small-scale plants use short-term planning technique, due to their resource constraints, non-uniform product demand, etc.

Cement Producing Plants also sometimes resort to this type of planning due to large fluctuations in demand from season to season. Short-term planning is designed to respond quickly to changes in production levels, market condition, etc.

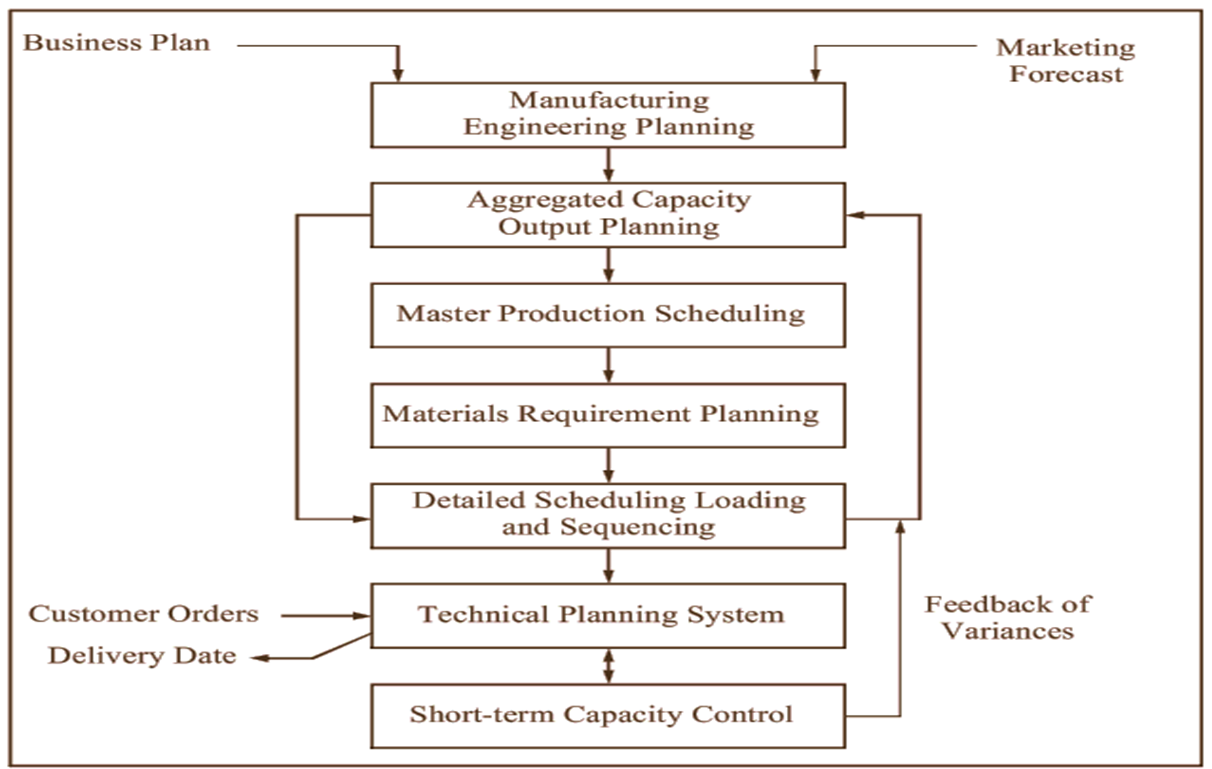

Integrated Production Planning System

It is desirable for every plant to design and develop an integrated production planning system. In such a system, all the components of production system are properly interlinked. Such a system focuses on aggregate level on a selective basis and does not interfere with detailed planning and scheduling. The main elements of integrated production planning system are shown as under: