Governors are mechanical devices used to regulate the speed of an engine by controlling the fuel or steam supply. The Porter Governor is an improved version of the Watt Governor that includes a central dead weight in addition to the rotating balls. This additional weight enhances stability and precision, making it more effective for speed control in engines.

Definition of Porter Governor

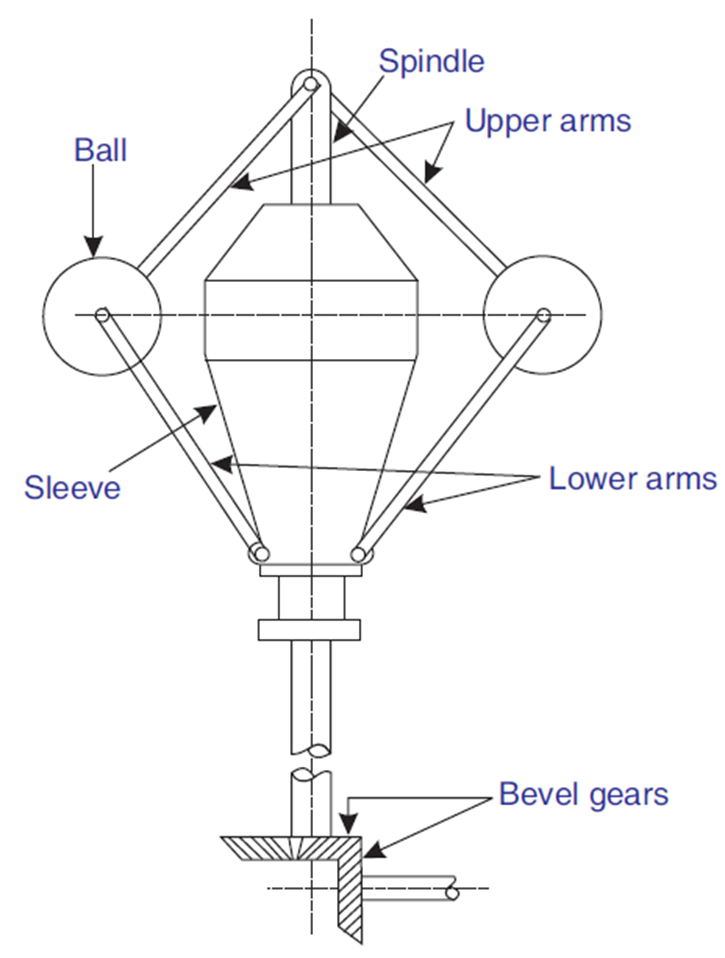

A Porter Governor is a type of centrifugal governor that consists of two rotating balls, upper and lower arms, a central spindle, a sleeve, and an additional dead weight. It regulates the speed of an engine by adjusting the throttle valve based on centrifugal force.

Parts of Porter Governor

- Balls (Flyweights): These rotate with the spindle and respond to speed variations by moving outward or inward.

- Upper Arms: These connect the balls to the spindle and help transmit motion.

- Lower Arms: These assist in moving the sleeve as the balls change position.

- Spindle: A rotating shaft connected to the engine that drives the governor.

- Sleeve: Moves up and down along the spindle to adjust the throttle valve.

- Dead Weight: Provides additional downward force, improving stability and control.

- Bevel Gears: Help transfer rotational motion from the engine to the governor.

Working Principle of Porter Governor

The working of the Porter Governor is based on the principle of centrifugal force. It adjusts the throttle valve based on the rotational speed of the governor. The steps are:

- At Normal Speed: The balls remain at a certain radius, and the sleeve stays at a constant height.

- When Speed Increases: The balls move outward due to an increase in centrifugal force. This causes the sleeve to rise, reducing the fuel supply by partially closing the throttle valve.

- When Speed Decreases: The balls move inward as centrifugal force decreases. This lowers the sleeve, increasing the fuel supply by opening the throttle valve.

- Equilibrium Position: The governor stabilizes the speed by maintaining the sleeve at an optimal height, ensuring a steady fuel supply.

Advantages of Porter Governor

- Increased Sensitivity: More responsive compared to the Watt Governor.

- Better Stability: The dead weight prevents excessive fluctuations.

- Improved Control: Provides more precise regulation of engine speed.

- Suitable for Medium-Speed Engines: Works efficiently in moderate-speed applications.

Disadvantages of Porter Governor

- Not Suitable for High-Speed Engines: Response time may be slower than modern electronic governors.

- Complex Design: More components than the Watt Governor make it slightly more difficult to manufacture and maintain.

- Limited Load Handling: Performance drops under large load variations.

Applications of Porter Governor

- Steam Engines: Used for regulating speed in early steam-powered engines.

- Stationary Engines: Applied in industrial machines requiring speed control.

- Locomotives: Used in railway engines during the early industrial period.

Conclusion

The Porter Governor is an effective speed-regulating device for medium-speed engines. By incorporating a dead weight, it improves stability and sensitivity compared to the Watt Governor. However, with advancements in electronic governors, its use has declined in modern applications. Despite this, it remains an important historical development in mechanical engineering.