An ideal transformer is loss free. But in the practical transformer there are following losses taking place.

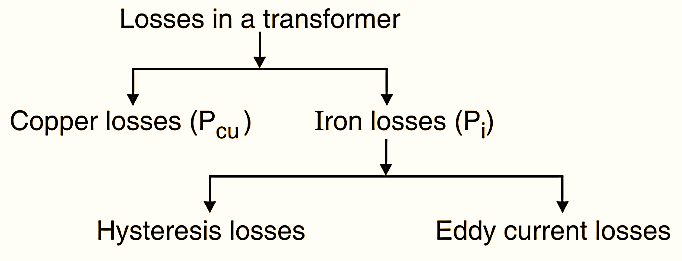

Figure1: Losses in a Transformer.

As shown in Fig. 1, the total loss in a transformer can be divided into two types namely the copper loss and the iron loss. The iron loss is further classified into two types namely the hysteresis loss and eddy current loss.

Copper Loss (Pcu) in a Transformer

The total power loss taking place in the windings resistance of a transformers is known as the copper loss.

Copper loss = Primary copper loss + secondary copper loss

The copper loss is denoted by Pcu.

\[{{P}_{cu}}=I_{1}^{2}{{R}_{1}}+I_{2}^{2}{{R}_{2}}\]

Where R1 and R2 are resistances of primary and secondary respectively.

Where,

\[I_{1}^{2}{{R}_{1}}\text{ = Primary copper loss}\]

and

\[I_{2}^{2}{{R}_{2}}\text{ = Secondary copper loss}\]

The copper loss should be kept as low as possible to increase the efficiency of the transformer. To reduce the copper loss, it is essential to reduce the resistances R1 and R2 of the primary and secondary windings. Copper losses are also called as variable losses as they are dependent on the square of load current. The relation between copper loss at full load and that at half load is as follows:

\[{{P}_{cu(HL)}}={{\left( \frac{1}{2} \right)}^{2}}{{P}_{cu(FL)}}=\frac{{{P}_{cu(FL)}}}{4}\]

Where,

\[{{\text{P}}_{cu(FL)}}=\text{ Copper loss at full load and}\]

\[{{\text{P}}_{cu(HL)}}\text{ = Copper loss at half load}\]

Iron Loss (Pi) in a Transformer

Iron loss Pi is the power loss taking place in the iron core of the transformer. It is equal to the sum of two components called hysteresis loss and eddy current loss.

Pi = Hysteresis Loss + Eddy current loss

Hysteresis Losses in a Transformer

The hysteresis loss taking place in a magnetic material. The area enclosed by the hysteresis loop of a material represents the hysteresis loss. Hence special magnetic materials should be used in order to reduce the hysteresis loss. Materials such as silicon steel has hysteresis loops with very small area. Hence such materials are preferred for the construction of core. Commercially such steel is called as Lohys, means low hysteresis materials. Mathematically the hysteresis loss is given by:

\[\text{Hysteresis loss = }{{K}_{H}}.B_{m}^{1.67}fV\text{ watt}\]

Where:

KH – Hysteresis constant,

Bm – Maximum flux density

f – Frequency and

V – Volume of the core

Thus the hysteresis loss is frequency dependent As we increase the frequency of operation, the hysteresis loss increase proportionally.

Eddy current losses in a Transformer

Due to the time varying flux, there is some induced emf in the transformer core. This induced emf causes some currents to flow though the core body. These currents are known as the eddy currents. The core is made of steel and has some finite resistance. Hence due to the flow of eddy currents, heat will be produced. The power loss due to the eddy currents is given by :

Eddy current loss = (Eddy current)2 × r

Where,

r – Resistance of the core.

The eddy current losses are minimized by using the laminated core. The core is manufactured as a stack of laminations rather than a solid iron core. These laminations are insulated from each other by means of a varnish coating on all the laminations. Hence each lamination acts as a separate core with a small cross-sectional area, providing a large resistance to the flow of eddy currents. Mathematically the eddy current loss is given by,

\[\text{Eddy current loss = }{{K}_{E}}B_{m}^{2}{{f}^{2}}{{T}^{2}}\]

KE – Eddy current constant,

T – core

Thus the eddy current loss also is frequency dependent. It is directly proportional to the square of operating frequency. It can be reduced by using the laminated core for transformer.

Hence the iron loss Pi of the total loss is dependent on the frequency but the copper loss Pcu is constant inspective of frequency. The iron loss is denoted by Pi. It is the sum of hysteresis and eddy current loss. Iron loss is a constant loss and does not depend on the level of load.

Total Loss in a Transformer

The total power loss taking place in a transformer can be obtained by adding the copper loss and iron losses together.

Total loss = Copper loss + Iron loss