The Lamont boiler is a high-pressure, forced circulation water-tube boiler. It was developed by Walter Douglas Lamont in the 1920s to overcome the limitations of natural circulation boilers. It operates by using a centrifugal pump to circulate water and generate high-pressure steam efficiently. It is widely used in power plants and industrial applications.

Parts of the Lamont Boiler

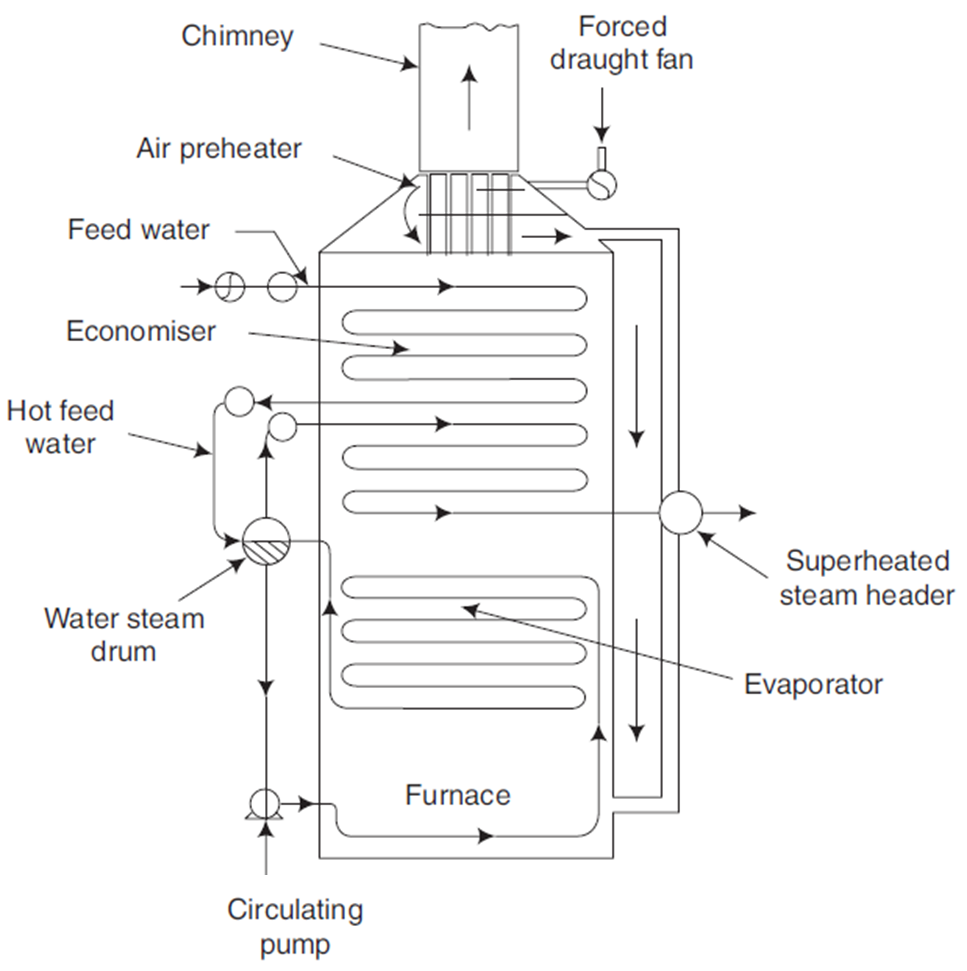

- Economizer: Preheats the feedwater using heat from flue gases, improving efficiency.

- Steam Drum: Stores water and separates steam from the water-steam mixture.

- Circulating Pump: Forces water through the evaporator tubes, ensuring continuous circulation.

- Evaporator Tubes: Where water is heated and partially converted into steam.

- Superheater: Further increases the temperature of steam before it is used in applications.

- Superheated Steam Header: Collects and distributes the superheated steam.

- Air Preheater: Preheats the air before combustion, improving fuel efficiency.

- Forced Draught Fan: Supplies air into the furnace to ensure complete combustion.

- Furnace: Burns fuel to generate heat for the boiler.

- Chimney: Expels exhaust gases after heat extraction.

Working Principle of the Lamont Boiler

The Lamont boiler works on the principle of forced circulation. A pump continuously circulates the water through the evaporator tubes, ensuring efficient heat transfer. The water is partially converted into steam, which is then separated in the steam separator drum. The steam is further superheated before being used for industrial applications.

Step-by-Step Working Process:

- Feedwater enters the economizer, where it is preheated by exhaust flue gases.

- The hot feedwater is then transferred to the steam drum.

- A circulating pump forces the water through the evaporator tubes located inside the furnace.

- The water absorbs heat, partially converting into steam.

- The water-steam mixture is then sent back to the steam drum.

- In the drum, steam is separated from water.

- The steam is then passed through a superheater to increase its temperature.

- The superheated steam is then supplied to turbines or industrial machinery.

- The flue gases exit through the chimney after transferring heat to the air preheater and economizer.

Advantages of Lamont Boiler

- Higher Efficiency: The forced circulation increases heat transfer and efficiency.

- Rapid Steam Generation: Capable of generating high-pressure steam quickly.

- Prevention of Overheating: The circulation pump avoids stagnation of water.

- Compact Design: Requires less space compared to some natural circulation boilers.

- Superheated Steam: Produces high-temperature steam suitable for turbines.

- Reduced Scaling: Forced circulation reduces the risk of scale deposition.

Applications of Lamont Boiler

- Power Plants: Used in thermal power stations for electricity generation.

- Marine Industry: Installed in ships for steam propulsion.

- Chemical Industries: Provides steam for various chemical processes.

- Textile Industry: Used for steam-based textile processing.

- Sugar Industry: Supplies steam for sugar refining processes.

Disadvantages of Lamont Boiler

- High Initial Cost: Expensive components like the circulation pump increase cost.

- Pump Dependency: Operation relies on the proper functioning of the circulating pump.

- Complex Design: More intricate than natural circulation boilers.

- Wear and Tear: Continuous circulation may cause erosion in tubes.

Conclusion

The Lamont boiler is an advanced water-tube boiler that uses forced circulation to improve efficiency and steam generation. Despite its complexity and higher costs, it is widely used in power plants and industries requiring high-pressure steam. Its ability to produce superheated steam makes it an essential component in many industrial applications.