An inclinometer, also referred to as a clinometer, is a device used to measure the angle of inclination or tilt of an object with respect to gravity. It is a vital instrument in various engineering, geotechnical, and construction applications.

Parts of an Inclinometer

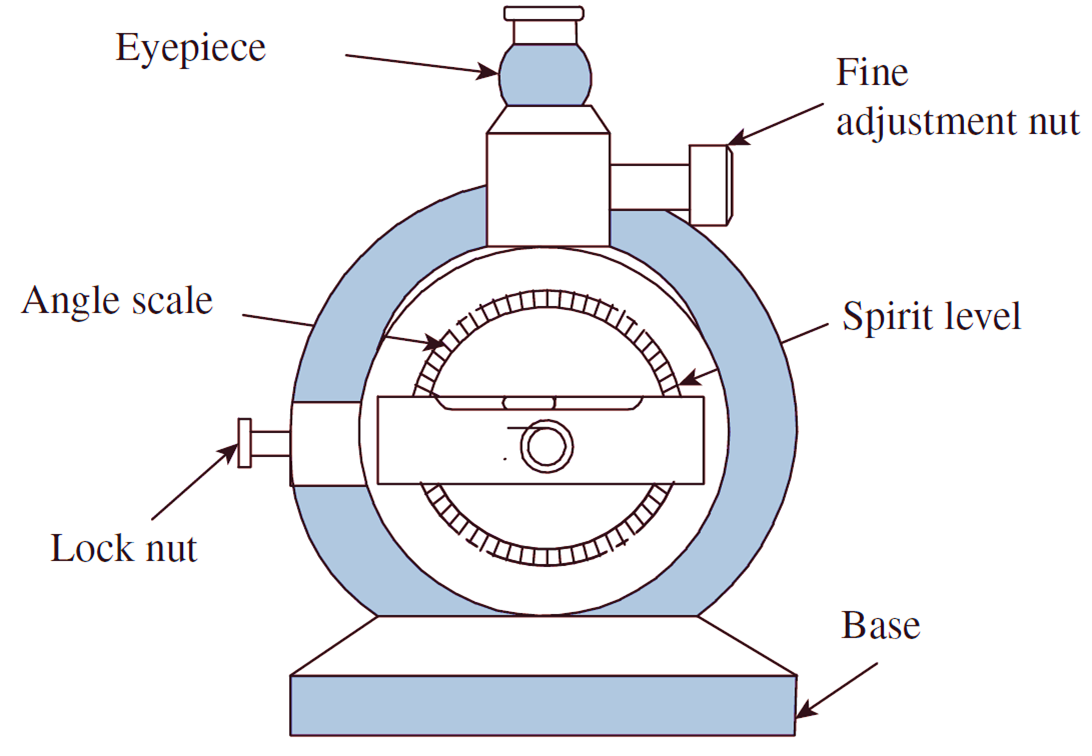

A standard inclinometer consists of the following components:

- Eyepiece: Used for sighting and aligning the inclinometer with the target object or surface.

- Fine Adjustment Nut: Provides precise control to adjust the angle for accurate measurement.

- Spirit Level: Ensures that the device is properly leveled during the measurement process.

- Angle Scale: A graduated scale that displays the tilt angle in degrees or other units of measurement.

- Lock Nut: Secures the inclinometer in place once the angle has been set or measured.

- Base: The foundation of the instrument, designed to rest on flat surfaces or attach to mounting equipment.

Working Principle of Inclinometer

The inclinometer operates based on the principle of gravity and angular displacement. The instrument’s internal mechanism, which may include a pendulum, fluid bubble, or electronic sensors, measures the tilt angle relative to a horizontal or vertical reference plane. The measured angle is then displayed on a scale or a digital screen.

Types of Inclinometers

Inclinometers come in various types based on their design, functionality, and applications:

| Type | Description | Applications |

|---|---|---|

| Digital Inclinometer | Uses digital sensors to measure angles with high precision and displays readings on a screen. | Engineering, construction, and surveying. |

| Mechanical Inclinometer | Employs a pendulum or liquid-filled container to indicate inclination. | Simple leveling tasks and industrial applications. |

| MEMS Inclinometer | Uses Micro-Electro-Mechanical Systems for small and precise angle measurements. | Robotics, aerospace, and automotive systems. |

| Bubble Inclinometer | Relies on a spirit level with a bubble to measure inclination angles. | Medical and physical therapy measurements. |

| Tilt Sensor | Electronic device that detects and measures tilt or inclination. | Heavy machinery and gaming devices. |

Advantages of Inclinometers

- High Precision: Modern inclinometers offer highly accurate angle measurements.

- Ease of Use: Simple to operate, especially digital models with intuitive interfaces.

- Versatility: Applicable in diverse fields such as geotechnics, construction, and aerospace.

- Portability: Lightweight and compact designs make them easy to carry and use in the field.

- Durability: Built to withstand harsh environments and challenging conditions.

Applications of Inclinometers

- Geotechnical Engineering: Used to monitor slope stability and ground movement.

- Construction: Ensures proper alignment and inclination of structures like walls and ramps.

- Aerospace: Measures the tilt of aircraft components during manufacturing and maintenance.

- Navigation: Helps in determining orientation and tilt for maritime and aviation purposes.

- Industrial Machinery: Monitors the tilt of machinery to prevent accidents and ensure stability.

- Robotics: Used in robotic systems to measure and adjust tilt angles for better performance.

Disadvantages of Inclinometers

- Calibration Requirements: Regular calibration is needed to maintain accuracy.

- Environmental Sensitivity: Performance can be affected by extreme temperatures and vibrations.

- Cost: Advanced models, especially those with digital sensors, can be expensive.

- Complexity in Borehole Applications: Installing and using borehole inclinometers requires specialized knowledge.

- Limited Measurement Range: Some inclinometers are restricted to specific tilt ranges.

Conclusion

Inclinometers are essential tools for measuring angles of tilt and inclination across a variety of industries. With advancements in technology, modern inclinometers offer enhanced accuracy and user-friendly designs, making them indispensable for professionals in engineering, construction, and beyond. Despite their limitations, their benefits far outweigh their disadvantages, solidifying their importance in precision measurements.