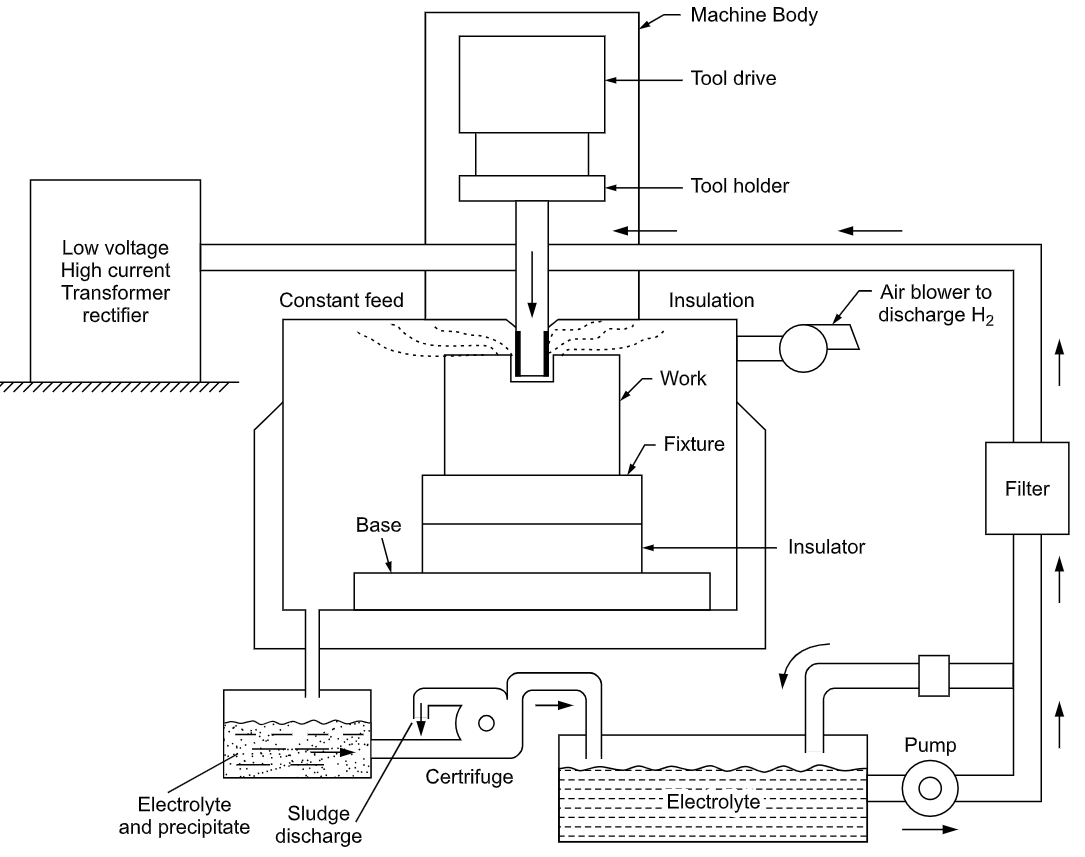

Figure 1: Electrochemical Machining (ECM).

1. Definition

Electrochemical Machining (ECM) is a non-traditional machining method that removes metal from a conductive workpiece by controlled anodic dissolution in an electrolyte under a low-voltage, high-current DC supply. Unlike conventional machining, ECM does not rely on cutting forces or mechanical abrasion; instead, atoms are removed as ions by electrochemical reaction. This makes ECM uniquely capable of machining very hard materials and producing complex geometries with superior surface finish and no thermal damage.

2. Working Principle of Electrochemical Machining (ECM)

ECM follows the laws of electrolysis: when direct current flows through an electrolyte between an anode and a cathode, metal at the anode dissolves proportionally to the amount of charge passed (Faraday’s laws). In ECM the workpiece is the anode (+) and the tool is the cathode (−). A conductive electrolyte is forced through the small inter-electrode gap; metal ions generated at the workpiece are transported away in the electrolyte and removed by filtration.

Chemical reactions (simplified)

At the anode (workpiece) metal atoms lose electrons and become ions, for example:

\[

\text{M} \rightarrow \text{M}^{n+} + ne^{-}

\]

At the cathode (tool) reduction typically produces hydrogen gas:

\[

2\text{H}_2\text{O} + 2e^{-} \rightarrow 2\text{OH}^- + \text{H}_2 \uparrow

\]

Because hydrogen evolves at the cathode, the tool does not suffer the same dissolution as the workpiece — hence negligible tool wear.

Key parameters

- Voltage: typically 5–30 V (DC)

- Current density: can be very high — from hundreds to thousands of A/cm²

- Inter-electrode gap: small and controlled, ~0.1–0.5 mm

- Electrolyte: conductive fluid (e.g. NaCl, NaNO₃)

3. Electrochemical Machining (ECM) Process — Step by Step

The ECM operation is a carefully controlled sequence that balances electrolyte flow, current supply and tool feed to remove metal at a predictable rate. Below is a typical workflow:

- Tool and workpiece preparation: The electrode (tool) is machined to the inverse of the desired profile. The workpiece is cleaned and clamped in a corrosion-resistant fixture.

- Align and set gap: The inter-electrode gap (IEG) is established and kept constant by controlled tool feed or servo mechanisms.

- Electrolyte circulation: A pump forces the electrolyte through the machining gap, removing ions, heat and hydrogen bubbles.

- Power on: DC power supply delivers constant current/voltage. The actual feed rate of the tool is tuned to match electrochemical dissolution.

- Continuous removal: Metal dissolves from the anode and is carried away as ionic species; these are converted to precipitates or remain dissolved until filtered out.

- Sludge handling: Filters and centrifuges separate solid precipitates and collect sludge for safe disposal or treatment.

- Finish and inspection: When the desired shape is achieved the current is turned off, the part rinsed, and final inspection and measurements are carried out.

Control systems synchronize tool feed and current so that the tool replicates the inverse geometry without touching the workpiece. The process produces no cutting forces or heat-affected zones, which is why it suits delicate and hardened components.

4. Diagram & Explanation of Electrochemical Machining (ECM)

The diagram (see Figure 1) illustrates an industrial ECM cell. Key visible systems are:

Low-voltage, high-current rectifier converts AC to the DC used for anodic dissolution.

The tool (cathode) is mounted in a driven holder that controls approach rate and dwell time.

Tank → pump → filter → machining gap → centrifuge → tank. Continuous flow flushes away ions and heat.

Debris and precipitates are removed by in-line filters and centrifuges; sludge is collected for disposal or treatment.

5. Main Parts of an ECM Machine

An ECM system brings together electrical, hydraulic and mechanical subsystems. The essential parts are:

- DC Power Supply: Low-voltage, high-current rectifier with fine current control.

- Tool (Electrode): Machined from copper, graphite, brass or stainless steel and shaped as the negative of the target profile.

- Workpiece Fixture: Insulated clamps and fixtures to hold conductive parts and prevent stray current removal.

- Electrolyte System: Tank, pump, piping, filters, heat exchanger and centrifuge to maintain cleanliness and temperature.

- Control & Feed Mechanism: Servo drives or precision screw feeds to maintain the inter-electrode gap and feed the tool at the correct rate.

- Gas Handling: Hydrogen generated during machining must be vented or removed with air blowers to avoid interference.

6. Advantages of Electrochemical Machining (ECM)

Electrochemical machining offers several important benefits that make it indispensable for certain industrial tasks:

- No tool wear: Because the cathode does not dissolve significantly, electrode life is effectively unlimited for many operations.

- Can machine very hard materials: ECM is independent of hardness — superalloys, hardened steels, and carbides can be machined.

- No heat-affected zone (HAZ): The chemical removal process produces no thermal damage, microcracks or residual stresses.

- Excellent surface finish: Mirror-like finishes are possible (Ra values in sub-micron ranges).

- Burr-free, stress-free parts: Ideal for delicate components like turbine blades, medical implants and fuel injectors.

- High material removal rate: Particularly when shaping complex cavities in hard materials, ECM can be faster than grinding or EDM.

7. Disadvantages & Limitations of Electrochemical Machining (ECM)

ECM is powerful, but it has trade-offs:

- High capital cost: Equipment, power electronics and corrosion-resistant fluid systems are expensive.

- Only conductive materials: Non-conductive materials such as ceramics and plastics cannot be machined directly (except hybrid processes).

- Electrolyte handling & disposal: Sludge contains metal compounds that must be treated; environmental compliance is mandatory.

- Potential for overcut and stray machining: Poor flow control or insulation can cause loss of dimensional accuracy.

- Power consumption: High currents mean significant electrical energy use.

- Corrosion risk: Plant and fixturing must be protected from corrosive electrolytes.

8. Typical Applications of Electrochemical Machining (ECM)

ECM is used where precision, quality and the ability to machine difficult materials are essential. Common applications include:

- Aerospace: Turbine blades, cooling channels, nozzles and compressor components made from Inconel or titanium.

- Automotive: Fuel injector geometry, precision valve seats, piston ring profiles.

- Medical: Implants, surgical instruments and micro components made from stainless steel or cobalt-chrome.

- Tool & Die: Dies, punches and molds for hardened tool steels.

- Electronics & Micro-machining: Small-diameter holes, PCB features and micro cavities.

- Defense & Energy: High-strength alloy components for missiles, pumps and valves.

9. Variants & Related Processes

Several techniques are derived from or combined with ECM:

- Precision ECM (PECM): Enhanced control systems for micrometer-level accuracy and repeatability.

- Electrochemical Grinding (ECG): Combines ECM principles with a conductive grinding wheel for finishing hard materials.

- Electrochemical Discharge Machining (ECDM): Hybrid process used for non-conductive materials like glass by combining spark erosion and electrochemical action.

10. Summary & FAQs

Summary: Electrochemical Machining is a contactless, stress-free, and heat-free machining method ideal for shaping conductive, hard, or complex parts. It uses DC power, controlled electrolyte flow, and precise feed control to dissolve metal at predictable rates. While ECM requires significant infrastructure and pollutant management, it remains unmatched when machining superalloys, producing burr-free finishes, and making complex geometries without thermal damage.

FAQs

| Question | Short answer |

|---|---|

| What materials can be machined? | Any electrically conductive metal — steels, nickel alloys, titanium, tungsten and more. |

| Does the tool wear? | Tool wear is negligible because the tool is the cathode and hydrogen evolution protects it. |

| Is ECM environmentally friendly? | Not inherently — sludge and electrolyte disposal need controlled treatment to meet environmental regulations. |

| What is the typical accuracy? | With precision control, ECM can achieve micrometer-level accuracy and excellent surface finish. |