The Cochran boiler is a vertical, multi-tubular, fire-tube boiler commonly used for small industrial applications. It is simple in design, occupies less floor space, and is known for its reliability.

What is Cochran Boiler?

A Cochran boiler is a vertical, fire-tube boiler with a hemispherical shell and multiple horizontal fire tubes. It uses solid, liquid, or gaseous fuels to generate steam for various industrial purposes.

Parts of Cochran Boiler

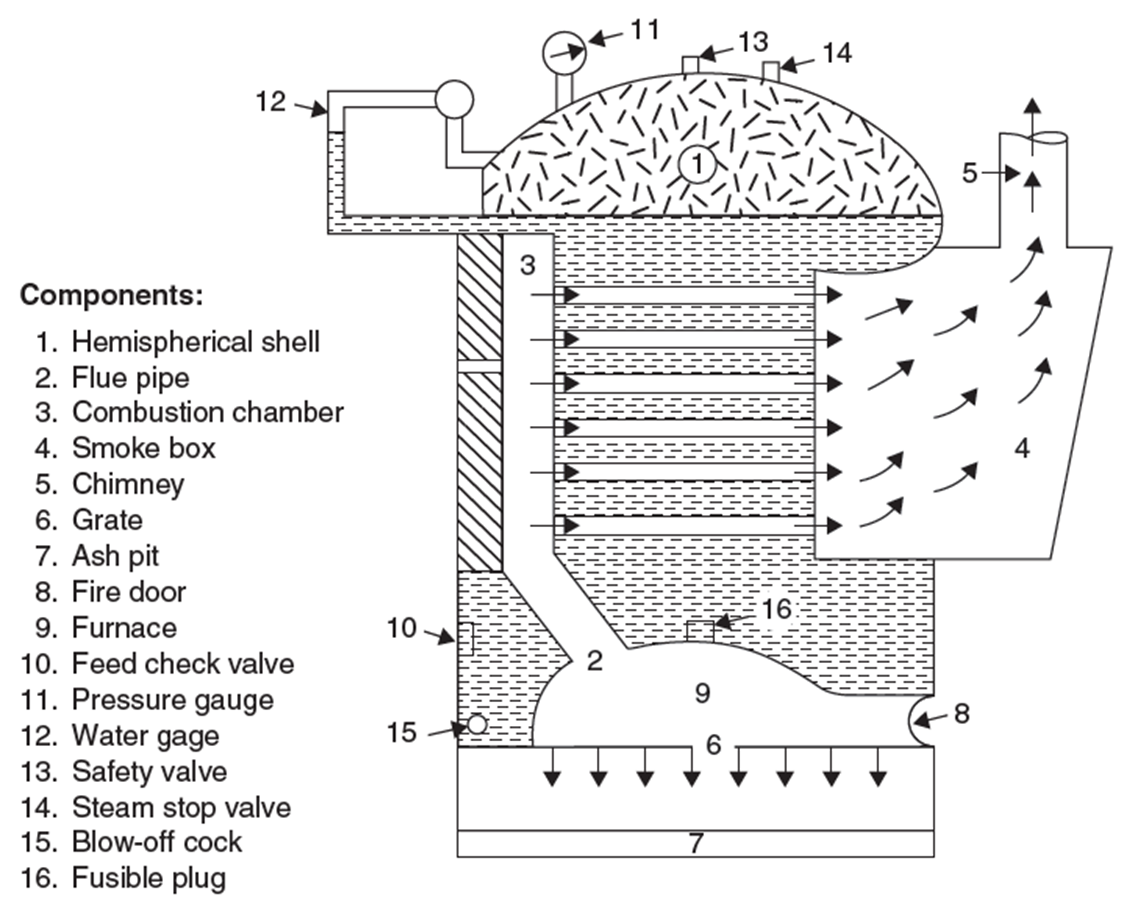

The main components of the Cochran boiler are illustrated in the provided diagram and described below:

- Hemispherical Shell: The boiler’s outer shell, designed in a hemispherical shape, increases strength and can withstand high pressures.

- Flue Pipe: A passage through which hot gases travel from the furnace to the smoke box.

- Combustion Chamber: The space where fuel combustion occurs, producing hot gases.

- Smoke Box: A chamber where flue gases are collected before being discharged through the chimney.

- Chimney: A vertical exhaust pipe that releases smoke and combustion gases into the atmosphere.

- Grate: A metal platform where solid fuel (coal) is burned.

- Ash Pit: A chamber below the grate where ash from burnt fuel is collected.

- Fire Door: A door for adding fuel to the furnace.

- Furnace: The main heat-producing area where fuel combustion occurs.

- Feed Check Valve: A valve that allows water to enter the boiler and prevents backflow.

- Pressure Gauge: Measures the steam pressure inside the boiler.

- Water Gauge: Indicates the water level inside the boiler.

- Safety Valve: Prevents excessive steam pressure by releasing extra steam when the pressure exceeds a set limit.

- Steam Stop Valve: Controls the steam flow from the boiler to the engine or process application.

- Blow-off Cock: Used to remove impurities, sediments, and excess water from the boiler.

- Fusible Plug: A safety device that melts if the boiler water level drops too low, preventing overheating and potential boiler explosions.

Working Principle of Cochran Boiler

The working process of a Cochran boiler follows these steps:

- Fuel Combustion: Solid fuel (coal) is fed through the fire door and burned on the grate. The combustion produces hot gases, which rise and pass through the flue pipe.

- Heat Transfer: The hot gases enter the fire tubes, transferring heat to the surrounding water. The water absorbs heat, converting it into steam.

- Steam Generation: As the water heats up, steam is formed and collected in the upper part of the boiler. The steam pressure increases, monitored by the pressure gauge.

- Steam Outlet: The steam stop valve releases steam as needed for industrial applications.

- Exhaust Gases: After transferring heat, the flue gases enter the smoke box and exit through the chimney into the atmosphere.

Advantages of Cochran Boiler

- Compact Design – Requires less floor space due to its vertical structure.

- Strong and Durable – The hemispherical shell provides strength to withstand high pressures.

- Easy to Operate – Simple construction makes it user-friendly.

- Cost-Effective – Economical for small industries.

- High Thermal Efficiency – Efficient heat transfer due to multiple fire tubes.

Applications of Cochran Boiler

- Small Industrial Plants – Used in food processing, chemical, and textile industries.

- Marine Applications – Used on ships for auxiliary steam generation.

- Power Plants – Generates steam for turbines in small-scale power plants.

- Hotels and Hospitals – Provides steam for heating and sterilization.

- Sugar Mills and Breweries – Utilized in sugar and beverage production.

Disadvantages of Cochran Boiler

- Limited Steam Production – Not suitable for large-scale industries requiring high steam output.

- Lower Efficiency Than Water-Tube Boilers – Fire-tube design limits heat transfer efficiency.

- Cleaning Difficulties – The vertical design makes internal cleaning challenging.

- High Maintenance – Requires regular maintenance of tubes and safety devices.

Conclusion

The Cochran boiler is a compact and efficient steam boiler widely used in small industries and marine applications. Despite some limitations, its simple design, cost-effectiveness, and reliability make it a popular choice for steam generation.