A Bevel Protractor is a precision instrument used for measuring angles with high accuracy. It is widely employed in engineering, machining, and inspection tasks to determine the angle between two surfaces. Equipped with a graduated circular scale and blades, the bevel protractor facilitates both angle measurement and layout tasks.

Working Principle of a Bevel Protractor

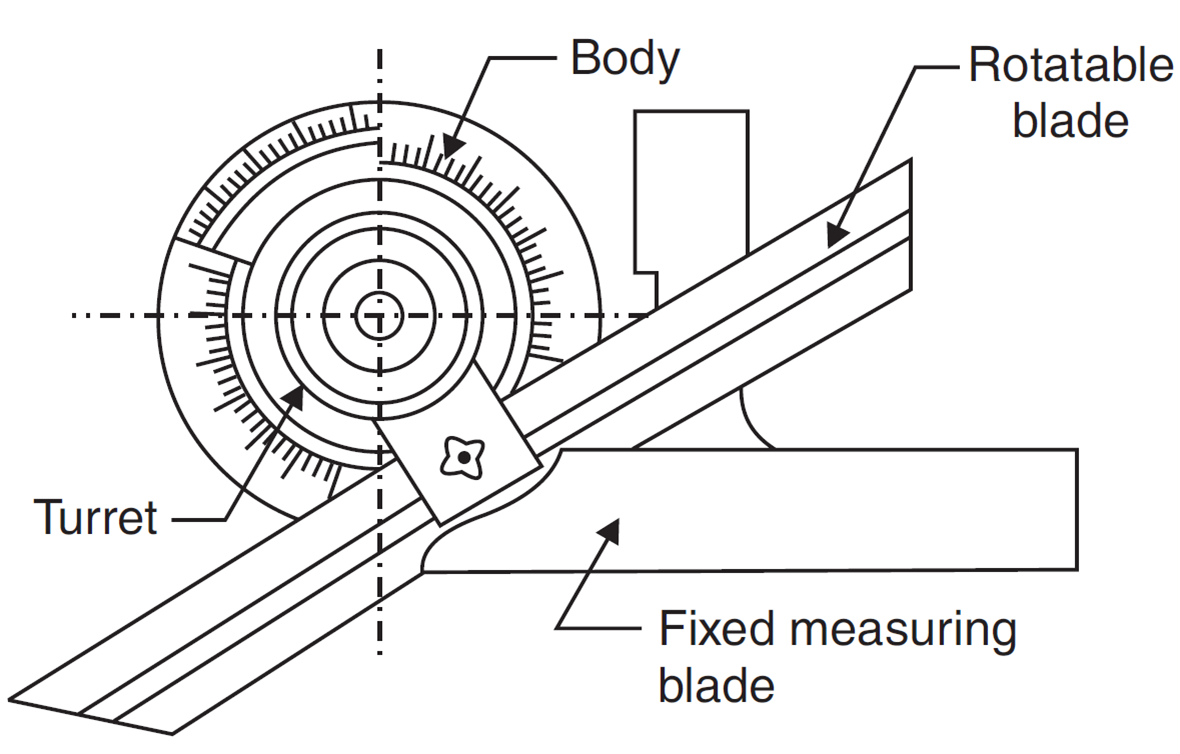

The working principle of a bevel protractor is based on the circular scale and adjustable blades. The main component is a graduated turret or protractor head, which measures angles in degrees. The rotatable blade is aligned with the desired surface, while the fixed measuring blade provides a reference line. The angle is then read from the protractor’s circular scale, which may include vernier graduations for finer measurements. The instrument allows for both external and internal angle measurements.

Parts of a Bevel Protractor

The bevel protractor consists of several components, each serving a specific purpose:

- Body: The main structure that holds all other components together.

- Protractor Head (Turret): A circular, graduated scale marked in degrees. It serves as the primary angle measurement tool.

- Fixed Measuring Blade: A non-movable blade attached to the body, used as a reference line.

- Rotatable Blade: A movable blade that can be adjusted to measure the angle relative to the fixed blade.

- Locking Knob: Used to secure the rotatable blade in place after alignment.

- Vernier Scale (Optional): Present in advanced bevel protractors, this scale provides finer angle readings, enhancing accuracy.

- Base or Support: Ensures stability during use and allows the instrument to sit firmly on the work surface.

Types of Bevel Protractors

Below is a table presenting the types of bevel protractors in a mobile-responsive format:

| Type | Description |

|---|---|

| Simple Bevel Protractor | Includes a basic graduated scale without a Vernier scale for standard measurements. |

| Vernier Bevel Protractor | Equipped with a Vernier scale for finer and more accurate angle readings. |

| Universal Bevel Protractor | Versatile and highly accurate, used for advanced engineering tasks. It typically includes a magnifying lens and a Vernier scale. |

| Digital Bevel Protractor | Features a digital display for easy and quick angle measurements. |

Least Count of a Bevel Protractor

The least count of a bevel protractor is the smallest angular measurement it can accurately read. It is calculated as:

Least Count = Value of one main scale division / Number of Vernier scale divisions

For example, if one main scale division equals 1° and the Vernier scale subdivides this into 12 parts:

Least Count = 1° / 12 = 5 minutes (5’)

This precision varies depending on the type of bevel protractor.

Accuracy of a Bevel Protractor

Bevel protractors offer high accuracy, typically within 5 minutes (1/12th of a degree) for Vernier models. Digital bevel protractors can provide even higher accuracy, often up to 0.1°.

Advantages of a Bevel Protractor

- High Precision: Accurate angle measurement due to Vernier scale or digital displays.

- Versatile Use: Can measure both internal and external angles.

- Ease of Use: Simple operation and adjustment for a wide range of applications.

- Durable Construction: Made from high-quality materials such as stainless steel.

- Wide Range: Suitable for measuring acute, obtuse, and right angles.

Applications of a Bevel Protractor

- Engineering and Machining: Measuring and verifying angles in manufacturing processes.

- Toolmaking: Ensuring accurate angles in dies, molds, and tools.

- Inspection: Verifying the angular dimensions of machined components.

- Metalworking: Layout work and scribing precise angles.

- Educational Use: Teaching precise measurement techniques in technical education.

Disadvantages of a Bevel Protractor

- Limited Measurement Range: Typically measures angles within 0° to 180°.

- Manual Handling Required: Precision depends on user skill and care.

- Time-Consuming: Vernier models require careful alignment and reading.

- Prone to Wear: Frequent use can lead to wear on the graduations, reducing accuracy.

- Cost: High-quality models, such as universal or digital bevel protractors, can be expensive.

Conclusion

The bevel protractor is a fundamental tool in precision engineering and machining, offering accurate angle measurement and layout capabilities. Understanding its working principle, components, and proper usage ensures maximum efficiency and reliability. While advanced digital alternatives are available, traditional Vernier and universal bevel protractors remain indispensable due to their durability and precision. Despite certain limitations, the bevel protractor’s versatility and accuracy make it an essential instrument in various industries.