A Bellows Pressure Gauge is a mechanical device used to measure pressure in fluid systems. It operates on the principle of expansion and contraction of bellows (a flexible, accordion-like component) when exposed to pressure variations. This movement is converted into a readable measurement using a mechanical linkage and pointer.

Parts of a Bellows Pressure Gauge

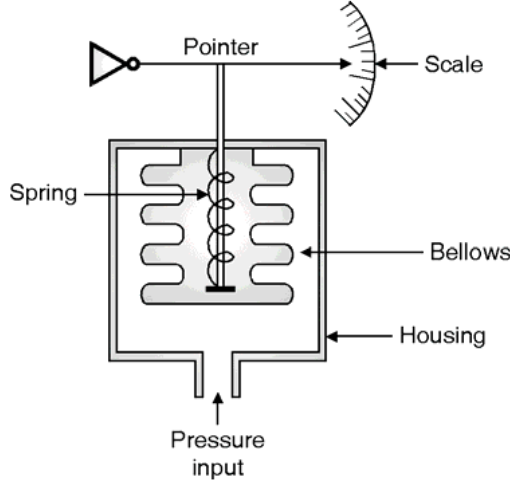

The major components of a bellows pressure gauge include:

- Bellows: A flexible, thin-walled, accordion-like component that expands or contracts based on applied pressure. Made of materials like stainless steel, phosphor bronze, or brass.

- Spring: Provides resistance against the bellows’ expansion to ensure accurate readings. Helps restore the bellows to its original position when pressure is removed.

- Pointer & Scale: The pointer is connected to a mechanical linkage that converts bellows movement into rotational motion. The scale is calibrated in appropriate pressure units (e.g., psi, bar, kPa) to display the measured pressure.

- Housing: Protects the internal components from environmental effects. Usually made of stainless steel or corrosion-resistant materials.

- Mechanical Linkage: Transfers and amplifies bellows movement to drive the pointer mechanism.

- Pressure Inlet: Allows external pressure to enter the bellows chamber.

Working Principle of a Bellows Pressure Gauge

The bellows pressure gauge functions based on the expansion and contraction of a metallic bellows when subjected to pressure. The working process is as follows:

- Pressure Input: The measured pressure is applied to the bellows chamber.

- Expansion of Bellows: As the pressure increases, the bellows expand against the opposing force of a spring. If the pressure decreases, the bellows contract due to the restoring force of the spring.

- Motion Transmission: The movement of the bellows is transferred to a mechanical linkage. This linkage amplifies the motion and moves a pointer attached to a calibrated scale.

- Pressure Indication: The pointer moves across the scale, providing a direct reading of the applied pressure.

Advantages of a Bellows Pressure Gauge

- High Sensitivity: The bellows mechanism allows for very small pressure variations to be detected.

- Wide Pressure Range: Suitable for measuring both low and moderate pressure levels.

- Compact & Lightweight: Compared to bourdon tube gauges, bellows gauges are more compact.

- No External Power Required: It is a purely mechanical device, making it suitable for remote locations.

- Good Accuracy: Provides reliable pressure readings with proper calibration.

- Can Measure Differential Pressure: Two bellows chambers can be used to measure differential pressure in certain designs.

Applications of Bellows Pressure Gauge

- Vacuum & Low-Pressure Measurements: Used in vacuum systems, HVAC applications, and industrial process monitoring.

- Medical Equipment: Found in ventilators, oxygen regulators, and other medical pressure-monitoring devices.

- Hydraulic & Pneumatic Systems: Used in hydraulic control systems and pneumatic pressure monitoring.

- Aerospace & Aviation: Used in altimeters, barometers, and aircraft cabin pressure monitoring.

- Power Plants & Refineries: Measures pressure in steam and gas processing plants.

- Industrial Process Control: Used in chemical plants, food processing, and pharmaceutical industries for pressure regulation.

Disadvantages of Bellows Pressure Gauge

- Limited High-Pressure Range: Not suitable for extremely high-pressure applications due to material constraints.

- Susceptibility to Temperature Changes: Temperature variations can affect material expansion, leading to slight inaccuracies.

- Mechanical Wear & Tear: Continuous expansion and contraction can cause fatigue over time, reducing lifespan.

- Less Rugged than Bourdon Tubes: Bellows are more delicate and prone to damage in harsh environments.

Conclusion

The Bellows Pressure Gauge is an essential instrument for measuring low to moderate pressures with high sensitivity. It is widely used in industrial, medical, and aerospace applications due to its precision and reliability. However, its limitations include mechanical wear and lower durability in high-pressure environments. Despite these drawbacks, it remains a vital tool in pressure measurement applications where accuracy is crucial.