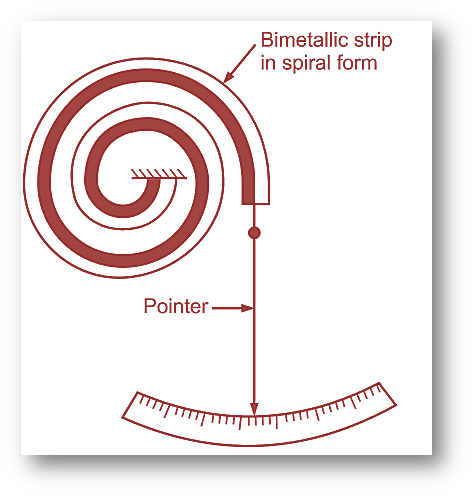

Fig. 1: Bimetallic Thermometer (Bimetallic strip in spiral form)

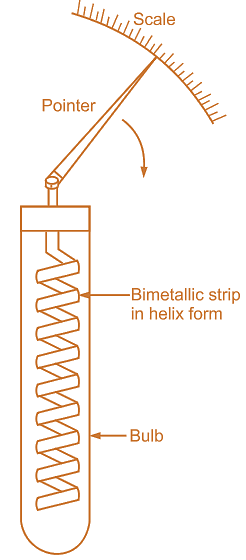

Working Principle of Bimetallic Thermometer

Two different materials having different coefficient of thermal expansion rigidly joined together, one on other to form a bimetallic strip.

Construction & Working of Bimetallic Thermometer

When bimetallic strip is fixed at one end, and heated from free end, it bends in the direction of material having low thermal coefficient of expansion.

Fig. 2: Bimetallic Thermometer (Bimetallic strip in spiral form.)

The bending moment of free end is connected to the pointer, which moves over calibrated scale. Usually bimetallic strip is wound in the form of helix form (see Figure 1) or in spiral form (see Figure 2). Its one end is fastened permanently to outer casing to form stopper and other end is connected to pointer.

A pointer moves over a circular dial as helix coils and uncoils with temperature variation. A typical bimetallic thermometer used between – 40°C to 320°C consist of Invar (36% Ni, 64% Fe) has low coefficient of expansion when joined to Ni-Mo alloy. A thermal well is provided at its outer tubing made of brass, steel or stainless steel for protection against corrosion and breakage.

Advantages of Bimetallic Thermometer

- Rugged construction.

- Simple and convenient design.

- No maintenance is required.

- It gives ± 1% accuracy.

- Overloading can be tolerated.

- Low cost.

Disadvantages of Bimetallic Thermometer

- Material is subjected to creep at high temperature.

- Speed of response is low.

Applications of Bimetallic Thermometer

- Frequently used in simple ON-OFF temperature control devices (Thermostats).

- In clocks to compensate temperature changes in clock mechanism.

- In circuit breakers to protect circuit from excess current.

- Time delay relays.

- Lamp flashers.

Advantages of Bimetal Helix Thermometer

- Low cost.

- Tough, not easily broken.

- Easily installed and maintained.

- Wide temperature range.

- Deflection is more, hence sensitivity is more.