A U-tube manometer is a device used for measuring pressure differences in fluids. It consists of a U-shaped tube filled with a liquid (usually mercury or water) and is used in applications requiring accurate pressure measurements.

Construction of U-Tube Manometer

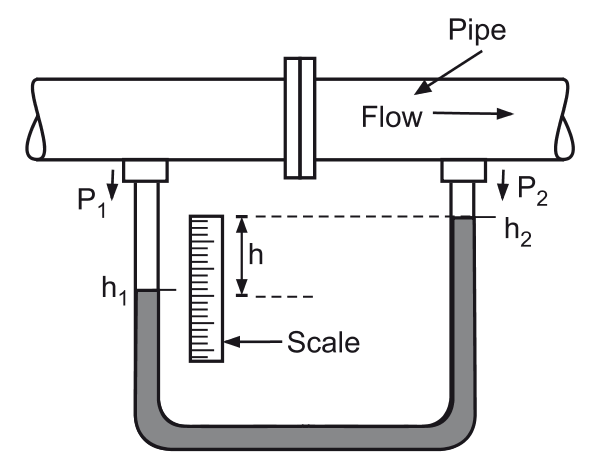

A typical U-tube manometer consists of:

- U-shaped glass tube – Transparent to allow measurement of liquid levels.

- Manometric liquid – Usually mercury, water, or other suitable fluids.

- Scale – Graduated to measure the height difference.

- Connections to pressure points – To compare two pressures, \( P_1 \) and \( P_2 \).

Working Principle of U-Tube Manometer

The U-tube manometer works on the principle of hydrostatic equilibrium. The pressure difference between two points in a fluid system is balanced by the weight of the liquid column in the manometer. The height difference in the two arms of the tube indicates the pressure difference.

Derivation of U-Tube Manometer Equation

Let:

\( P_1 \) = Pressure at one end of the tube

\( P_2 \) = Pressure at the other end

\( h \) = Height difference of the liquid column

\( \rho \) = Density of the manometric liquid

\( g \) = Acceleration due to gravity

Applying the hydrostatic pressure equation:

\[

P_1 + \rho g h_1 = P_2 + \rho g h_2

\]

Since

\[

h = h_2 – h_1

\]

The pressure difference can be written as:

\[

\Delta P = P_1 – P_2 = \rho g h

\]

This equation shows that the pressure difference is directly proportional to the height difference of the liquid in the U-tube.

Advantages of U-Tube Manometer

- Simple construction and easy to use.

- Highly accurate and reliable.

- Requires no external power.

- Can measure both positive and negative pressures.

- Works with various liquids for different sensitivity requirements.

Applications of U-Tube Manometer

- Measuring pressure differences in pipelines.

- Used in laboratories for fluid mechanics experiments.

- HVAC systems for air pressure measurement.

- Calibration of pressure gauges.

- Industrial process monitoring.

Disadvantages of U-Tube Manometer

- Not suitable for very high-pressure measurements.

- Mercury-based manometers are hazardous.

- Requires careful handling to avoid errors.

- Cannot be used for dynamic pressure measurements.

Conclusion

The U-tube manometer remains one of the most precise instruments for measuring pressure differences in fluids. Despite its limitations, its accuracy and simplicity make it an essential tool in fluid mechanics and industrial applications.