A Forced Draught Cooling Tower is a type of cooling tower where a fan or blower is used to force air through the tower to enhance the cooling effect. It is typically used in industrial applications to cool water or other fluids by evaporative cooling, transferring heat from the water to the air.

Working Principle of a Forced Draught Cooling Tower

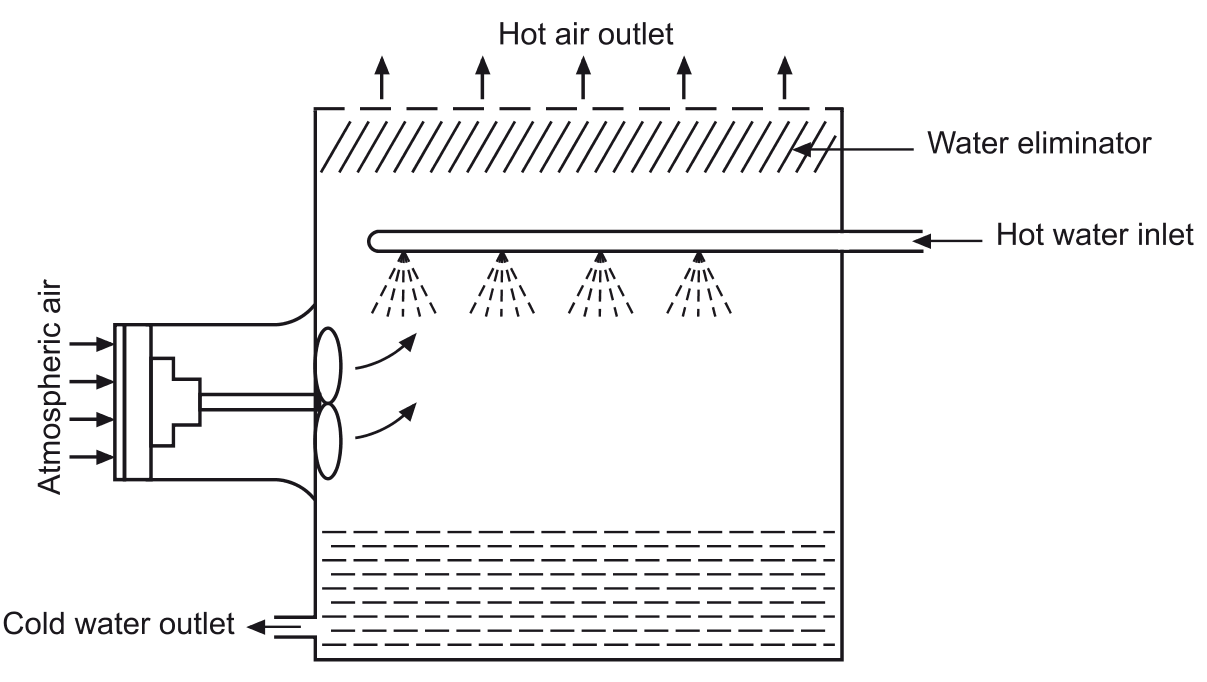

The forced draught cooling tower operates by utilizing a mechanical fan to push atmospheric air into the tower, creating forced convection. The process can be described as follows:

- Hot water enters the cooling tower through an inlet pipe.

- The hot water is distributed through spray nozzles that break it into fine droplets.

- A fan or blower at the base forces atmospheric air into the tower.

- The air flows against the falling water droplets, enhancing heat transfer.

- Some water evaporates, taking away heat and cooling the remaining water.

- The cooled water is collected at the bottom and discharged through a cold water outlet.

- The warm, humid air rises and exits through the hot air outlet, passing through a water eliminator to prevent water loss due to drift.

Parts of a Forced Draught Cooling Tower

- Hot Water Inlet – Carries hot water from the industrial process into the cooling tower.

- Spray Nozzles – Distribute water into fine droplets for efficient cooling.

- Fan/Blower – Forces air into the system to enhance heat exchange.

- Water Eliminator – Prevents water droplets from escaping along with exhaust air.

- Cold Water Outlet – Collects and directs the cooled water back into circulation.

- Tower Structure – Supports the entire cooling tower components.

- Air Inlet – Allows atmospheric air to enter and mix with the water.

Advantages of Forced Draught Cooling Towers

- Better Control of Airflow – The fan ensures consistent cooling regardless of environmental conditions.

- Compact Design – Typically smaller than natural draught cooling towers.

- Higher Efficiency – Faster cooling due to forced air circulation.

- Less Affected by Weather – Works efficiently in both hot and cold climates.

- Ideal for Industrial Use – Common in power plants, refineries, and HVAC systems.

Applications of Forced Draught Cooling Towers

- Power Plants – Used to cool condenser water in thermal power stations.

- Chemical Plants – Maintains optimal temperature in chemical processes.

- HVAC Systems – Provides cooling in air conditioning systems.

- Refineries – Used in petroleum refining and other industrial processes.

- Food Processing – Helps in temperature control for production lines.

Disadvantages of Forced Draught Cooling Towers

- Higher Energy Consumption – Requires mechanical fans, increasing power usage.

- Increased Maintenance – Fans and motors require regular servicing.

- Higher Operational Costs – Due to electricity consumption and maintenance needs.

- Noise Pollution – Fans can produce significant noise levels.

- Prone to Corrosion – Exposure to moisture can lead to material degradation over time.