A Natural Draught Cooling Tower (NDCT) is a specialized heat exchange structure used in power plants and industrial facilities to remove excess heat by utilizing natural airflow. Unlike mechanical draft cooling towers, NDCTs rely on temperature and density differences to drive air circulation, making them energy-efficient and cost-effective over time.

Working Principle of a Natural Draught Cooling Tower

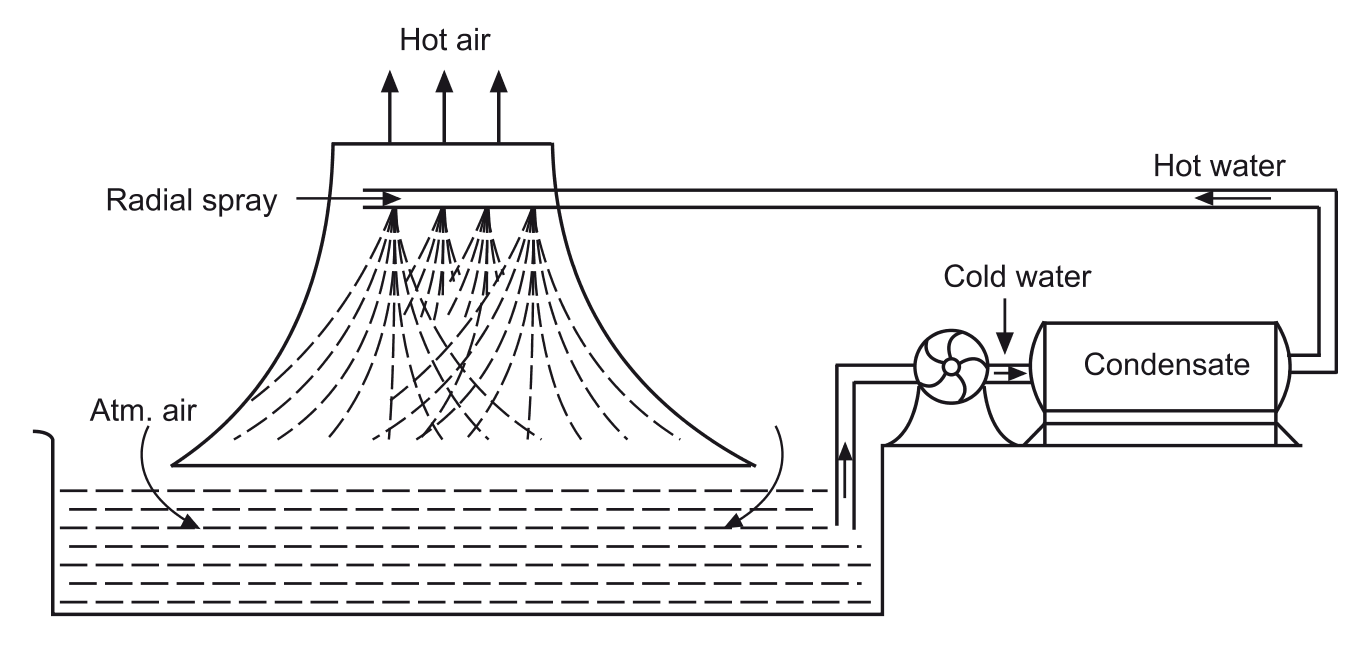

The working principle of a natural draught cooling tower is based on the buoyancy effect. Warm air rises due to its lower density compared to the surrounding cooler air. This movement creates a natural convection current that draws in cool atmospheric air from the base of the tower, facilitating heat exchange. The process involves:

- Hot water from the condenser is pumped to the top of the cooling tower.

- Radial spray nozzles distribute the water evenly inside the tower.

- Air enters the base of the tower due to the natural pressure difference.

- As the hot water droplets come into contact with the air, evaporative cooling occurs, reducing the water temperature.

- Cooled water collects at the bottom and is recirculated to the condenser.

- Warm, moist air rises naturally due to its lower density and exits from the top of the tower.

This self-sustaining process enables continuous cooling without the need for fans or external power sources.

Parts of a Natural Draught Cooling Tower

- Hyperbolic Structure: The tower is shaped like a hyperbola to enhance structural stability and improve airflow efficiency.

- Water Distribution System: Comprises pipes and radial spray nozzles that evenly distribute warm water over the cooling fill or directly into the air.

- Cooling Fill (Optional): Helps maximize heat transfer by increasing the surface area for evaporation.

- Air Intake Louvers: Located at the base of the tower to allow fresh air entry and prevent water splashing out.

- Drift Eliminators: Prevents water droplets from escaping with the exiting air, reducing water loss.

- Hot Water Basin: A collection area at the top of the tower where warm water is stored before being sprayed downward.

- Cold Water Basin: Collects the cooled water at the base for recirculation.

- Makeup Water System: Replaces lost water due to evaporation and drift losses.

- Natural Draught Effect: The core principle enabling airflow through temperature-induced pressure differences.

Advantages of Natural Draught Cooling Towers

- Energy Efficiency – No external fans or blowers required, reducing power consumption.

- Low Maintenance Costs – Fewer moving parts result in lower maintenance and repair needs.

- High Durability – Constructed using reinforced concrete or FRP, making them long-lasting.

- Environmentally Friendly – Uses natural airflow rather than mechanical means, reducing carbon footprint.

- Self-Sustaining Operation – Once built, it operates efficiently with minimal human intervention.

- Scalability – Can handle large thermal loads, making them suitable for power plants and industrial units.

- Minimal Noise Pollution – Operates silently compared to mechanical draft towers.

Applications of Natural Draught Cooling Towers

- Thermal Power Plants – Used for cooling steam condensers in coal, gas, and nuclear power plants.

- Petrochemical Industries – Helps in cooling refinery processes and chemical plants.

- Steel and Metallurgical Plants – Removes excess heat from industrial operations.

- HVAC Systems – Applied in large air conditioning and refrigeration systems.

- Desalination Plants – Used for cooling processes in seawater desalination facilities.

Disadvantages of Natural Draught Cooling Towers

- High Initial Cost – Requires significant capital investment for construction and installation.

- Large Space Requirement – Needs a vast area due to its massive size.

- Slow Response Time – Takes longer to adjust to sudden load variations.

- Limited to Specific Locations – Not suitable for regions with low ambient temperatures and humidity.

- Structural Challenges – Prone to cracks and weather damage over long operational periods.

- Dependent on Weather Conditions – Performance is affected by wind speed, temperature, and humidity variations.

Conclusion

Natural Draught Cooling Towers provide an effective and energy-efficient way of cooling industrial processes by leveraging natural convection. Despite their high initial costs and space requirements, their long-term advantages make them a preferred choice for large-scale power and industrial applications. By utilizing atmospheric air and eliminating the need for mechanical fans, they significantly reduce operational costs and environmental impact.