A surface condenser is a type of heat exchanger used in power plants and industrial applications to condense exhaust steam from turbines into water. It operates under vacuum conditions to improve efficiency by maximizing the temperature difference between steam and coolant.

Parts of a Surface Condenser

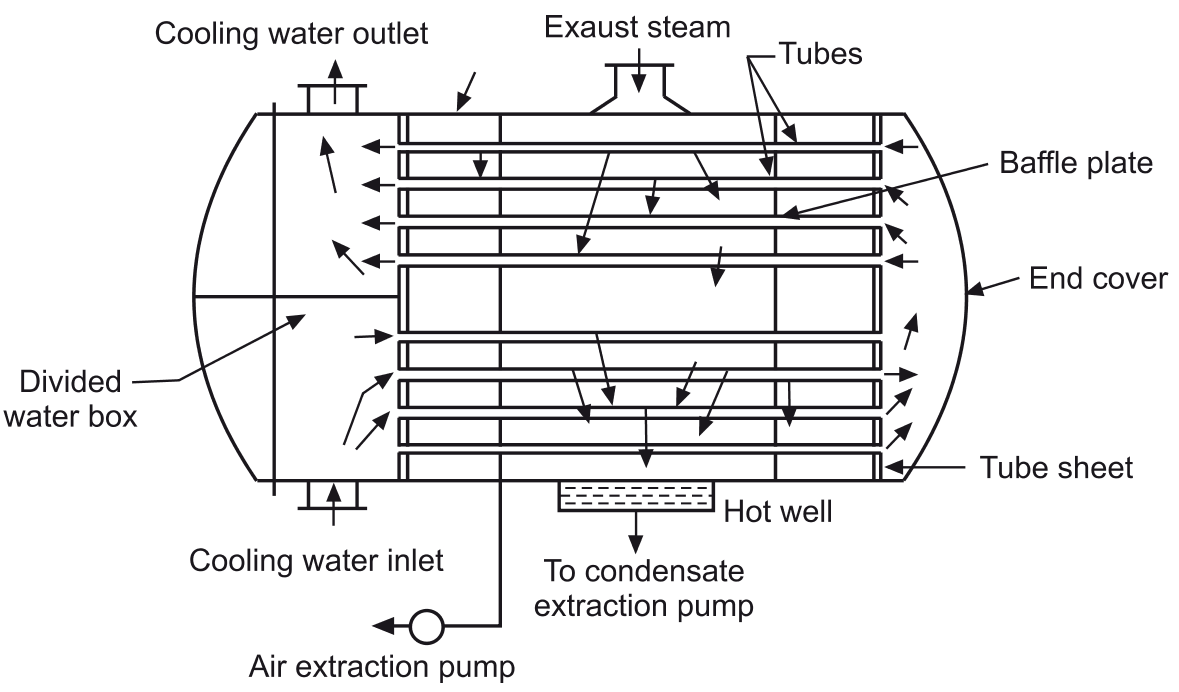

- Tubes: Made of copper, brass, or stainless steel and responsible for heat exchange between steam and cooling water.

- Tube Sheet: Supports and holds the tubes in place.

- Baffle Plates: Directs the flow of steam to ensure uniform distribution.

- End Covers: Seals the ends of the condenser.

- Divided Water Box: Ensures proper flow of cooling water.

- Hot Well: Collects the condensate for reuse in the boiler.

- Cooling Water Inlet and Outlet: Allows cooling water to enter and exit.

- Air Extraction Pump: Removes non-condensable gases to maintain vacuum conditions.

Working Principle of a Surface Condenser

The surface condenser works by allowing exhaust steam from turbines to pass over a set of tubes through which cooling water flows. The heat from the steam is transferred to the cooling water, causing the steam to condense into water. The condensed water (condensate) is collected in a hot well and recirculated in the system.

Step-by-step working process:

- Exhaust steam enters the condenser from the turbine.

- The steam comes in contact with the outer surface of the cooling tubes.

- Heat transfer occurs, and the steam loses heat, converting it into condensate.

- The condensate is collected in the hot well.

- The non-condensable gases are extracted using an air extraction pump.

- The cooling water carries the absorbed heat away and is discharged.

Types of Surface Condensers

| Type | Description |

|---|---|

| Down Flow Surface Condenser | Steam enters from the top and flows downward. |

| Central Flow Surface Condenser | Steam enters centrally and moves outward. |

| Regenerative Surface Condenser | Reheats some steam before entering the boiler. |

| Evaporative Surface Condenser | Uses water spray to increase heat transfer efficiency. |

| Jet Condenser (Not a True Surface Condenser) | Mixes steam directly with cooling water. |

Difference Between Surface Condenser and Jet Condenser

| Feature | Surface Condenser | Jet Condenser |

|---|---|---|

| Steam and Water Contact | Steam does not mix with cooling water. | Steam mixes directly with cooling water. |

| Efficiency | Higher efficiency due to separate cooling water. | Lower efficiency as steam and water mix. |

| Condensate Usability | Condensate is reusable in boilers. | Condensate is lost with cooling water. |

| Maintenance | Requires periodic cleaning. | Less maintenance required. |

| Application | Used in power plants and industrial applications. | Used in smaller plants where water supply is abundant. |

Conclusion

Surface condensers play a vital role in enhancing thermal efficiency in power plants and industrial systems. Despite some limitations, their advantages make them essential components in energy and manufacturing industries.