The Babcock and Wilcox boiler is a high-pressure, water-tube boiler that utilizes natural circulation. It was designed and developed by George Herman Babcock and Stephen Wilcox in the 19th century. This boiler is widely used in power plants, industries, and marine applications due to its efficiency and ability to produce high-pressure steam.

Parts of the Babcock and Wilcox Boiler

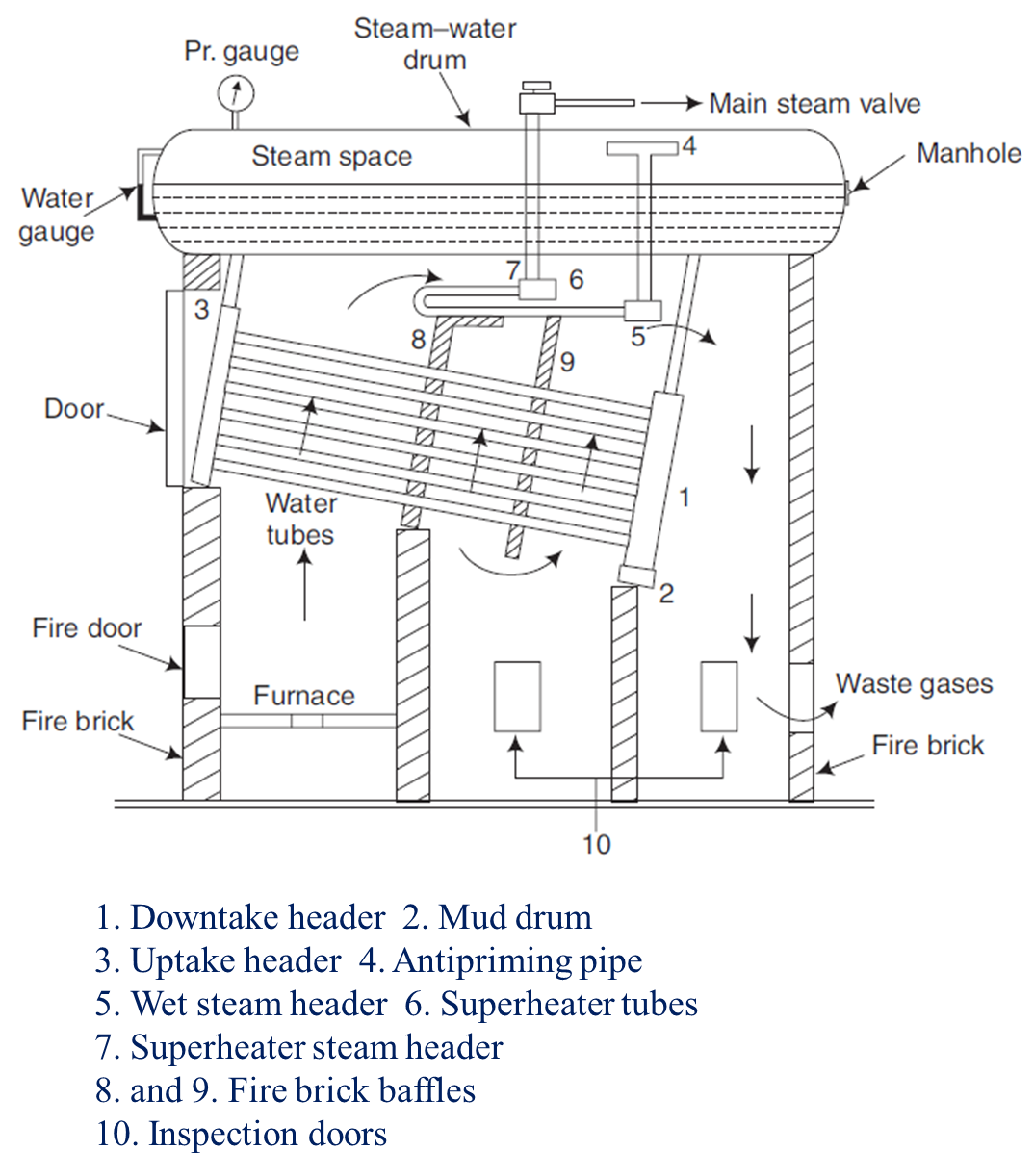

- Downtake Header: It is a large pipe that directs the water from the steam drum to the water tubes. This ensures proper circulation of water within the system.

- Mud Drum: Positioned at the bottom of the water tubes, the mud drum collects sediments and impurities that settle from the water. This helps prevent blockages and scaling in the water tubes.

- Uptake Header: Located at the top of the water tubes, the uptake header collects the steam generated in the tubes and directs it to the steam drum for further processing.

- Antipriming Pipe: The steam generated often contains water droplets, which can affect turbine performance. The antipriming pipe removes these water droplets, ensuring only dry steam is delivered.

- Wet Steam Header: This component stores and delivers the wet steam before it undergoes superheating.

- Superheater Tubes: These tubes receive steam from the wet steam header and increase its temperature further. This ensures that the steam remains dry and superheated before being used in power generation.

- Superheater Steam Header: It is the final collection point for the superheated steam before it is sent to the main steam line for industrial or mechanical applications.

- Fire Brick Baffles: Fire brick baffles are heat-resistant structures placed inside the boiler to direct the hot gases over the water tubes efficiently. These improve heat transfer and boiler efficiency.

- Additional Fire Brick Baffles: These secondary baffles further enhance heat transfer by ensuring maximum contact of hot gases with the water tubes.

- Inspection Doors: These doors are strategically placed to allow easy inspection and maintenance of the boiler’s internal parts. They help in cleaning and repairing the boiler without significant downtime.

Working Principle of Babcock and Wilcox Boiler

The Babcock and Wilcox boiler operates on the principle of water tubes being heated externally by hot flue gases. The water inside the inclined tubes gets converted into steam, which is collected in the steam drum. The generated steam is then further superheated and used for power generation or industrial processes.

Step-by-Step Working Process:

- Water is fed into the steam-water drum through the feedwater pump.

- The inclined water tubes are partially filled with water and arranged in a manner that allows for maximum heat absorption.

- The furnace burns fuel (typically coal or oil), producing hot flue gases.

- These flue gases pass over the water tubes, heating the water inside and converting it into steam.

- The steam-water mixture rises to the steam drum, where steam is separated from water.

- The generated wet steam passes through the antipriming pipe to remove water droplets.

- The dry steam then enters the superheater tubes, where its temperature is further increased.

- Finally, the superheated steam exits through the main steam valve and is utilized for mechanical or industrial applications.

- The flue gases exit through the chimney after transferring heat.

Advantages of Babcock and Wilcox Boiler

- High Efficiency: Heat transfer is enhanced due to the large heating surface.

- Quick Steam Generation: Water-tube design enables rapid steam production.

- Ability to Work at High Pressures: It can operate at pressures up to 100 bar or more.

- Safe Operation: Water tubes contain minimal water, reducing the risk of explosion.

- Easy Maintenance: Components can be inspected and replaced without dismantling the entire system.

- High Durability: The boiler is made from strong materials, making it long-lasting.

- Better Fuel Utilization: Efficient combustion ensures minimal fuel wastage.

Applications of Babcock and Wilcox Boiler

- Power Plants: Used to generate steam for electricity production.

- Marine Industry: Installed in ships for steam propulsion.

- Chemical and Process Industries: Used in chemical plants for steam supply.

- Textile Industry: Provides steam for textile processing.

- Sugar Industry: Used for steam generation in sugar mills.

- Paper Industry: Supplies steam for paper production processes.

Disadvantages of Babcock and Wilcox Boiler

- High Initial Cost: The complex design and materials increase initial expenses.

- Bulky Design: Requires large installation space.

- Water Treatment Required: To prevent scaling and corrosion, water must be treated properly.

- Complex Operation: Requires skilled operators for efficient functioning.

Conclusion

The Babcock and Wilcox boiler is one of the most widely used water-tube boilers due to its high efficiency, safety, and capability to operate at high pressures. Despite its few disadvantages, it remains a preferred choice in industries requiring high-pressure steam. Its robust design, efficient heat transfer, and reliability make it an essential part of power plants and industrial applications.