The Benson boiler is a high-pressure, water-tube boiler that operates on the principle of supercritical steam generation. It is a once-through boiler, meaning that water is converted into steam without the need for a drum. It was invented by Mark Benson in 1922 and is widely used in modern power plants for efficient steam generation.

Parts of Benson Boiler

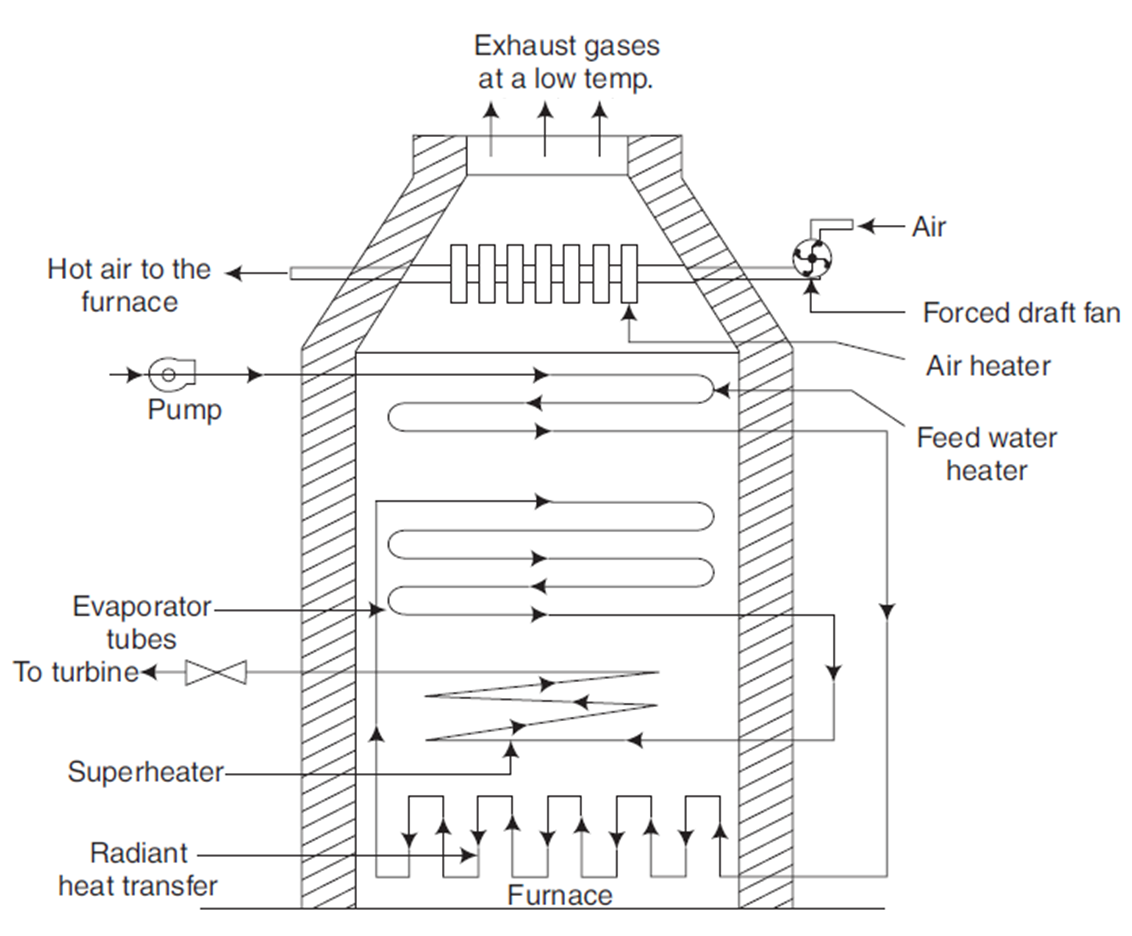

- Pump: Pressurizes the feed water before entering the boiler.

- Feed Water Heater: Pre-heats the feed water before entering the economizer.

- Economizer: Utilizes exhaust gases to preheat the water, improving efficiency.

- Evaporator Tubes: Converts water into steam through radiant and convective heat transfer.

- Superheater: Further heats the steam to increase its temperature and energy.

- Furnace: Provides heat energy for the conversion of water into steam.

- Radiant Heat Transfer Section: Transfers heat through radiation for efficient steam generation.

- Forced Draft Fan: Supplies air for combustion, ensuring an efficient burning process.

- Air Heater: Preheats the air before it enters the furnace, increasing combustion efficiency.

- Exhaust Gas Outlet: Releases low-temperature gases after heat extraction.

Working Principle of Benson Boiler

The Benson boiler works on the principle of supercritical steam generation, where water is heated beyond its critical point (22.1 MPa, 374°C). At this point, water directly converts into steam without the formation of bubbles, eliminating the need for a steam drum. The absence of a drum reduces heat loss and increases efficiency. The feed water is pressurized by a pump and passed through economizers, evaporator tubes, and superheaters to generate high-temperature, high-pressure steam for turbines.

Advantages of Benson Boiler

- Higher Efficiency: Eliminates heat loss due to the absence of a steam drum.

- Rapid Start-Up: Can start faster compared to conventional boilers.

- Compact Design: Requires less space due to the elimination of the drum.

- Reduced Weight: Lighter construction makes installation easier.

- No Bubble Formation: Eliminates thermal stress issues, enhancing reliability.

- Higher Pressure Capability: Operates at supercritical pressures, improving steam quality.

Applications of Benson Boiler

- Power Plants: Used in thermal power stations for electricity generation.

- Nuclear Power Plants: Utilized in nuclear reactors for high-efficiency steam production.

- Marine Applications: Applied in ships requiring high-pressure steam for propulsion.

- Industrial Heating: Used in industries for high-temperature process heating.

Disadvantages of Benson Boiler

- High Initial Cost: Expensive components increase installation costs.

- Complex Control System: Requires precise monitoring and control.

- Water Treatment Required: High-quality feed water is necessary to prevent corrosion.

- Risk of Overheating: Requires careful operation to avoid overheating of tubes.

The Benson boiler remains a preferred choice for modern high-pressure steam applications due to its superior efficiency, compact design, and ability to operate at supercritical pressures.