A Proell Governor is a type of centrifugal governor used in engines to regulate their speed by adjusting the fuel supply. It is a modified version of the Watt Governor, designed for higher sensitivity and better stability.

The main distinguishing feature of the Proell Governor is that the fly balls (masses) are attached to the extension of the lower arms, making the system more responsive to speed variations.

It is mainly used in steam engines, turbines, and other mechanical systems that require precise speed control.

Working Principle of Proell Governor

The Proell Governor operates based on centrifugal force. As the engine speed increases, the balls experience greater centrifugal force, moving outward and lifting the sleeve. This movement is then transferred to a throttle valve, which reduces fuel supply, slowing the engine down. If the engine speed decreases, the opposite happens, increasing fuel supply.

Step-by-Step Working Mechanism

- Normal Speed Condition: At a constant speed, the balls maintain a fixed position, keeping the throttle valve steady.

- Increase in Engine Speed: If the engine speed increases, the centrifugal force acting on the balls increases. The balls move outward, lifting the sleeve. This movement operates the lever mechanism, reducing the throttle valve opening. The fuel supply decreases, reducing the engine speed.

- Decrease in Engine Speed: If the engine speed decreases, the centrifugal force reduces. The balls move inward, lowering the sleeve. The throttle valve opens more, increasing fuel supply. This increases engine speed back to normal.

The Proell Governor thus helps in automatic speed regulation by controlling the throttle valve.

Parts of Proell Governor

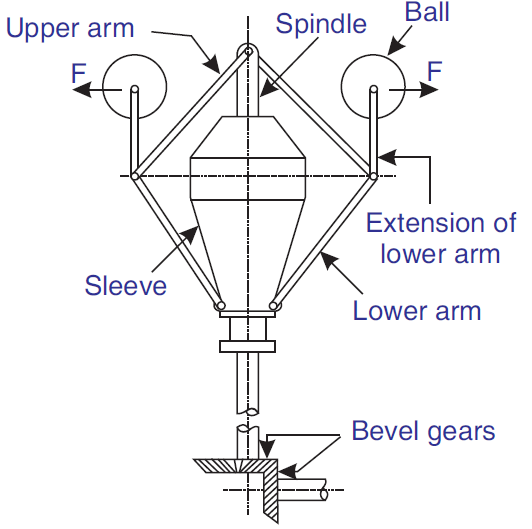

The Proell Governor consists of several essential components:

- Balls (Masses): Two heavy metal balls are attached to the lower arm extensions. They experience centrifugal force, controlling the fuel supply.

- Upper Arms: Connects the balls to the central spindle. Free to pivot and move outward/inward as the balls move.

- Lower Arms: These arms extend below the spindle and are connected to the sleeve. They support the fly balls at their extended ends, improving sensitivity.

- Extension of Lower Arm: The lower arms are extended to hold the fly balls away from the spindle. This modification increases governor responsiveness.

- Sleeve A movable sleeve: that slides up and down the spindle. Its movement adjusts the throttle valve, controlling fuel supply.

- Spindle (Vertical Shaft): A vertical shaft connected to the engine via bevel gears. It rotates at a speed proportional to the engine speed.

- Bevel Gears: Transfers motion from the engine shaft to the governor. Ensures that the governor’s speed corresponds to the engine speed.

- Throttle Valve: Connected to the sleeve via a lever mechanism. Controls the fuel/steam supply to the engine.

Advantages of Proell Governor

The Proell Governor offers several advantages over conventional governors:

- Higher Sensitivity: The extended lower arms allow greater movement, making the governor more responsive to speed changes.

- Better Stability: Due to its improved mechanical design, it provides better speed stability in engines.

- More Effective for High-Speed Engines: Unlike the Watt Governor, which is limited to low-speed engines, the Proell Governor is suitable for higher speeds.

- Reduced Hunting: Hunting (excessive fluctuations in speed) is minimized due to its increased sensitivity and stability.

- Efficient Fuel Regulation: Helps in maintaining optimum fuel efficiency by automatically adjusting the fuel supply.

- No External Power Required: Operates purely on centrifugal force, making it energy-efficient.

- Suitable for Steam Turbines: It is often used in steam turbines and other mechanical systems requiring precise speed control.

Applications of Proell Governor

The Proell Governor is widely used in various industrial and mechanical applications:

- Steam Engines: Used in steam engines to regulate speed and prevent overloading.

- Power Plants: Applied in small and large power plants to maintain generator speed.

- Textile and Manufacturing Machines: Ensures a constant operating speed in textile industries.

- Locomotives: Used in early steam locomotives for automatic speed control.

- Marine Engines: Helps regulate speed in marine propulsion systems.

- Industrial Pumps and Compressors: Maintains constant speed in fluid and air compression systems.

Disadvantages of Proell Governor

Despite its advantages, the Proell Governor has some limitations:

- More Complex than Watt Governor: Due to the extended lower arms, its construction is slightly more complex.

- Limited to Medium-Speed Engines: While it works well at higher speeds than the Watt Governor, it is still not ideal for very high-speed engines.

- Requires Maintenance: Due to the additional moving parts, wear and tear is higher than in simpler governors.

- Sensitivity Can Be Too High: If not properly calibrated, the governor may become too sensitive, leading to excessive throttle adjustments.

- More Expensive: Compared to basic centrifugal governors, it requires more material and manufacturing effort, increasing cost.

Conclusion

The Proell Governor is a highly effective speed-regulating device used in steam engines and other mechanical systems. Its improved sensitivity, better stability, and suitability for medium-speed engines make it a preferred choice over the traditional Watt Governor. However, its complexity and maintenance requirements mean it is not always the best option for very high-speed applications.