A locomotive boiler is a fire-tube, multi-tube, horizontal, internally fired type of boiler primarily used in railway engines. It generates steam by burning solid fuel (coal) and is designed to produce high-pressure steam for operating locomotive engines efficiently.

The locomotive boiler consists of a large cylindrical shell with multiple fire tubes, a firebox, and a steam dome, enabling it to produce high steam pressure rapidly.

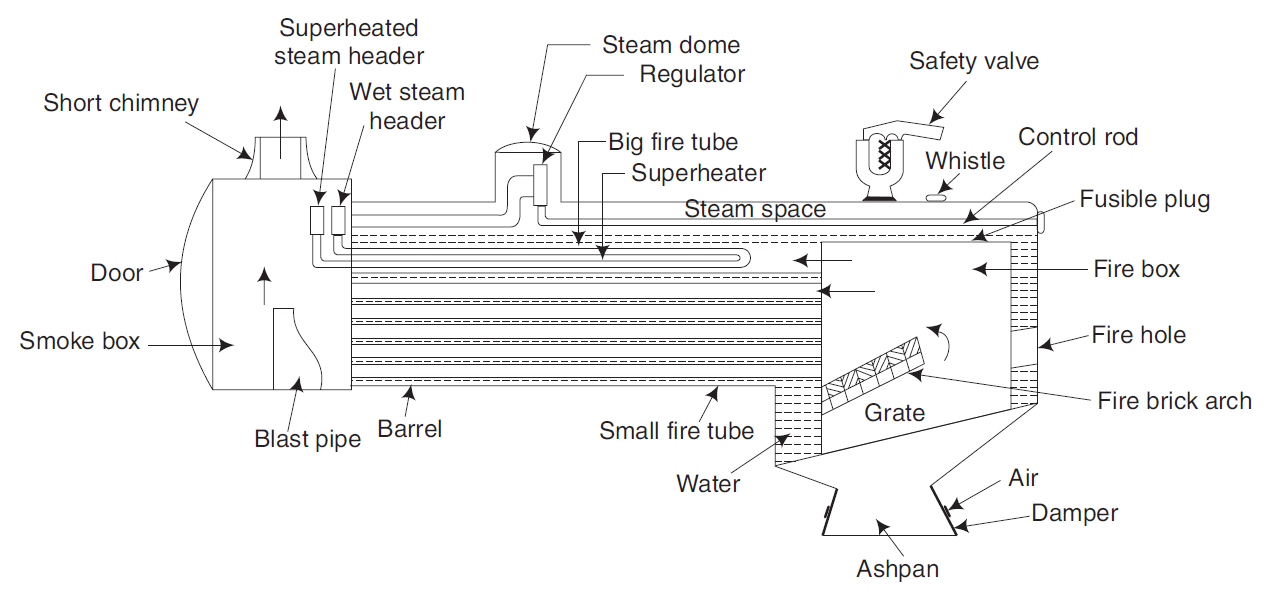

Parts of a Locomotive Boiler

A locomotive boiler consists of the following main components:

- Firebox: It is where coal is burned to generate heat. The grate holds the fuel, while the firebrick arch directs the flames.

- Grate: A perforated platform inside the firebox that supports the burning coal and allows air circulation.

- Fire Tubes (Small and Big): Multiple small fire tubes carry hot gases through the water-filled boiler shell to maximize heat transfer.

- Barrel: The cylindrical part of the boiler that contains water and fire tubes.

- Steam Dome: Located at the top of the boiler to collect and regulate steam.

- Regulator: Controls the flow of steam from the boiler to the engine.

- Safety Valve: Prevents excessive pressure build-up by automatically releasing steam if the pressure exceeds safe limits.

- Whistle: A safety device that produces sound signals using escaping steam.

- Superheater (Optional): Increases the temperature of steam before it enters the engine, improving efficiency.

- Wet Steam Header & Superheated Steam Header: Distribute the generated steam for different uses.

- Blast Pipe: Directs exhaust steam to the chimney, creating a draught that enhances combustion.

- Chimney (Short Chimney): Allows combustion gases to escape.

- Smoke Box: Collects exhaust gases before releasing them through the chimney.

- Fusible Plug: A safety device that melts if the water level becomes too low, preventing overheating.

- Ashpan & Damper: The ashpan collects burnt fuel remains, while the damper regulates airflow.

Working Principle of Locomotive Boiler

The working of a locomotive boiler is based on the Rankine cycle, where fuel combustion generates heat, converting water into steam, which is then utilized to drive a steam engine.

Step-by-Step Working Process

- Fuel Combustion in the Firebox: Coal or wood is burned in the firebox on the grate, generating high-temperature gases. The firebrick arch directs the hot gases towards the fire tubes.

- Heat Transfer through Fire Tubes: The hot gases pass through the small fire tubes, heating the surrounding water inside the boiler shell. The water absorbs heat, converting into steam. The steam collects in the steam space.

- Steam Collection in the Steam Dome: The steam rises into the steam dome, where it is regulated by the steam regulator. The steam flows into the superheater (if present) to increase efficiency.

- Exhaust of Gases: The combustion gases pass through the smoke box and exit via the short chimney, creating a draught that enhances combustion.

- Steam Utilization: The steam is directed to the locomotive’s cylinders, where it expands and pushes pistons, converting thermal energy into mechanical work.

Advantages of Locomotive Boiler

- High Steam Generation Rate: Due to the large heating surface and multiple fire tubes, it produces steam rapidly.

- Compact and Portable: Designed for mobility, making it suitable for railway locomotives.

- Simple Construction: Easy to manufacture and repair.

- Effective Heat Transfer: Multiple fire tubes ensure efficient heat transfer from gases to water.

- High Efficiency: The presence of a superheater improves thermal efficiency.

- Continuous Steam Supply: Can maintain a constant steam output, which is essential for railway engines.

Applications of Locomotive Boiler

- Railway Engines: Historically used in steam locomotives for transportation.

- Marine Applications: Used in old steam-powered ships and boats.

- Industrial Applications: Employed in steam-powered machines in industries before modern boilers were developed.

- Portable Steam Engines: Used in agricultural and construction machinery in earlier times.

Disadvantages of Locomotive Boiler

- Low Efficiency in Stationary Applications: Designed for mobility, making it less suitable for stationary applications.

- Limited Steam Storage: Cannot store large amounts of steam, requiring continuous operation.

- High Fuel Consumption: Consumes more fuel compared to modern boilers.

- Complex Maintenance: Requires frequent maintenance to prevent tube clogging and ash buildup.

- Large Space Requirement: Due to its long cylindrical shape, it requires significant space.

Conclusion

The locomotive boiler is a classic boiler type that played a crucial role in the development of steam locomotion. While it has largely been replaced by modern boilers, it remains an essential topic in engineering and historical studies.