A profile projector, also known as an optical comparator, is a metrological device used to measure and inspect the dimensions of manufactured components with high precision. It projects a magnified shadow of the workpiece onto a screen, allowing detailed inspection and measurement.

Parts of a Profile Projector

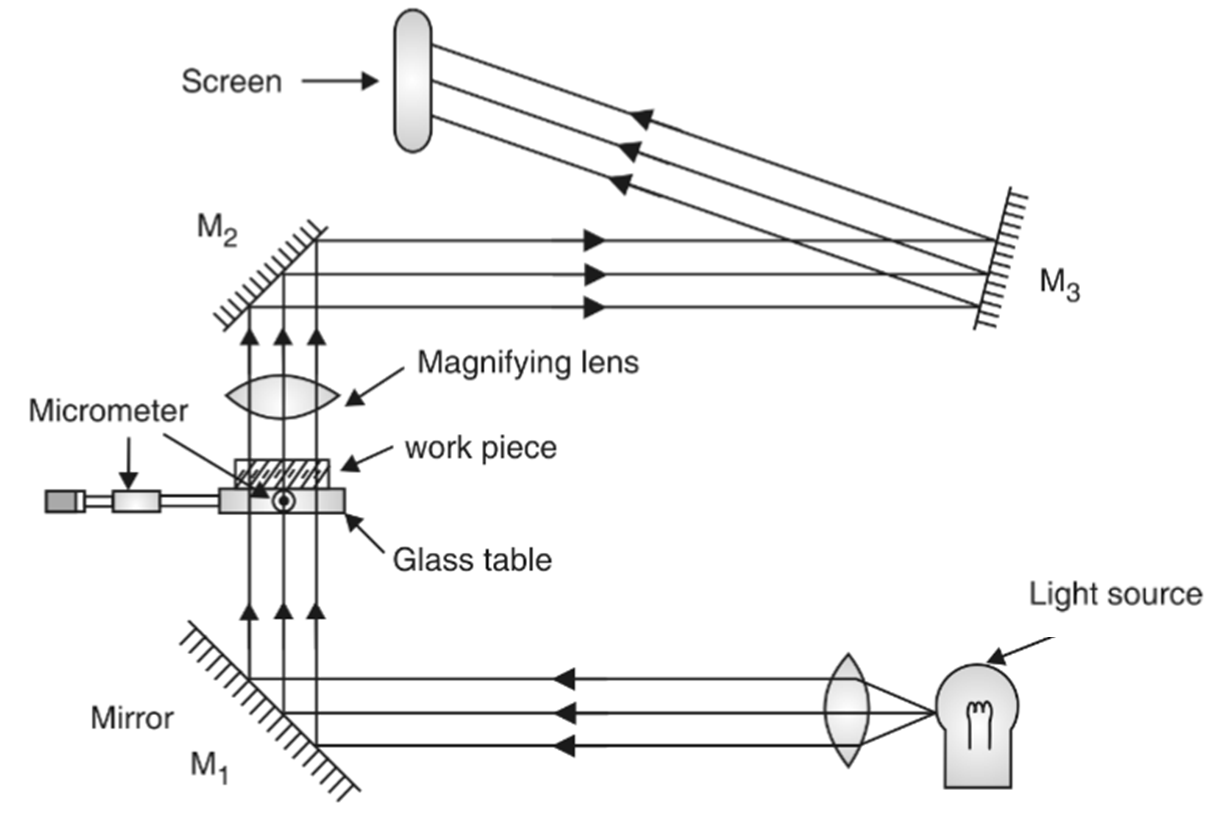

- Light Source – Provides uniform illumination for projection.

- Lenses (Objective & Projection Lenses) – Magnify the image of the workpiece.

- Glass Stage (Worktable) – Supports the workpiece, usually made of transparent glass.

- Micrometer & Digital Readouts – Enable precise movement and measurement of the workpiece.

- Magnifying Lens – Assists in detailed inspection.

- Mirrors (M1, M2, M3) – Reflect the image onto the viewing screen.

- Projection Screen – Displays the magnified shadow of the workpiece for measurement.

- Fixture & Clamps – Hold the workpiece securely.

- Rotary Table – Rotates the workpiece for angular measurements.

Working Principle of a Profile Projector

The profile projector operates on the principle of optical magnification and projection. A light source illuminates the workpiece, creating a shadow that is magnified through a lens system and projected onto a screen. By comparing the projected image with a reference template or using precision measurement tools, accurate dimensions can be determined.

Steps of Operation:

- Illumination – A light source emits light through a condenser lens.

- Projection – The light passes through or around the workpiece placed on a glass stage.

- Magnification – The image is magnified using objective lenses.

- Reflection – Mirrors direct the light towards a screen.

- Observation & Measurement – The projected image is compared to templates or measured using micrometers.

Types of Profile Projectors

| Type | Description |

|---|---|

| Horizontal Profile Projector | Projects the magnified image in a horizontal plane, suitable for large and heavy components. |

| Vertical Profile Projector | Projects the magnified image in a vertical plane, ideal for small, lightweight parts. |

| Digital Profile Projector | Incorporates digital display and software integration for precise automated measurement. |

| CNC Profile Projector | Computer-controlled for automated inspection and high-accuracy measurement. |

Least Count of Profile Projector

The least count of a profile projector depends on the measurement system used, such as the micrometer, digital readout, or vernier scale. Typically, the least count is:

- Optical micrometer: 0.001 mm (1 micron)

- Digital readout systems: 0.001 mm to 0.01 mm

- Vernier scale: 0.02 mm

The least count represents the smallest measurable unit of the device, ensuring high precision in dimensional inspection.

Advantages of Profile Projector

- High Precision – Allows accurate measurement of small components.

- Non-Contact Measurement – No physical contact reduces the risk of deformation.

- Ease of Use – Simple operation with clear visualization.

- Versatile Applications – Suitable for various industries like mechanical, aerospace, and electronics.

- Magnification Options – Provides different magnification levels for detailed analysis.

- Comparison with Standards – Easily compares dimensions with templates.

Applications of Profile Projector

- Manufacturing Industry – Inspection of machined components.

- Aerospace & Automotive – Measurement of precision-engineered parts.

- Electronics Industry – Ensures micro-component accuracy.

- Medical Equipment Manufacturing – Inspects surgical tools and implants.

- Tool & Die Industry – Verification of dies and molds.

- Quality Control Labs – Ensures adherence to design specifications.

Disadvantages of Profile Projector

- Limited to 2D Measurements – Cannot measure depth or 3D structures.

- Dependence on Operator Skill – Accuracy depends on the operator’s expertise.

- Image Distortion – Errors may arise due to improper alignment or lens imperfections.

- Expensive Maintenance – High-precision lenses and components require careful handling.

- Limited Field of View – Large components may not fit on the worktable.

Conclusion

A profile projector is an essential tool in metrology, offering precision measurement, non-contact inspection, and ease of use. While it has limitations, its advantages make it indispensable in industries requiring high accuracy. Advancements in digital and CNC-based optical comparators further enhance its capabilities.