A Vernier Height Gauge is a precision instrument used for measuring vertical distances to a high degree of accuracy. It is commonly employed in manufacturing and engineering environments for scribing lines, checking heights, and ensuring precise measurements during machining and quality control processes. The instrument combines a main scale and a Vernier scale to achieve fine measurement readings.

Working Principle of a Vernier Height Gauge

The Vernier Height Gauge operates on the principle of a Vernier scale, which allows users to read measurements more precisely than a standard ruler or scale. The main scale provides the primary reading, while the Vernier scale subdivides the smallest unit of the main scale into finer increments. The difference between the graduations of the main scale and the Vernier scale helps determine the least count of the instrument. By aligning the scales and locking the slider, accurate height measurements or markings can be achieved

Parts of a Vernier Height Gauge

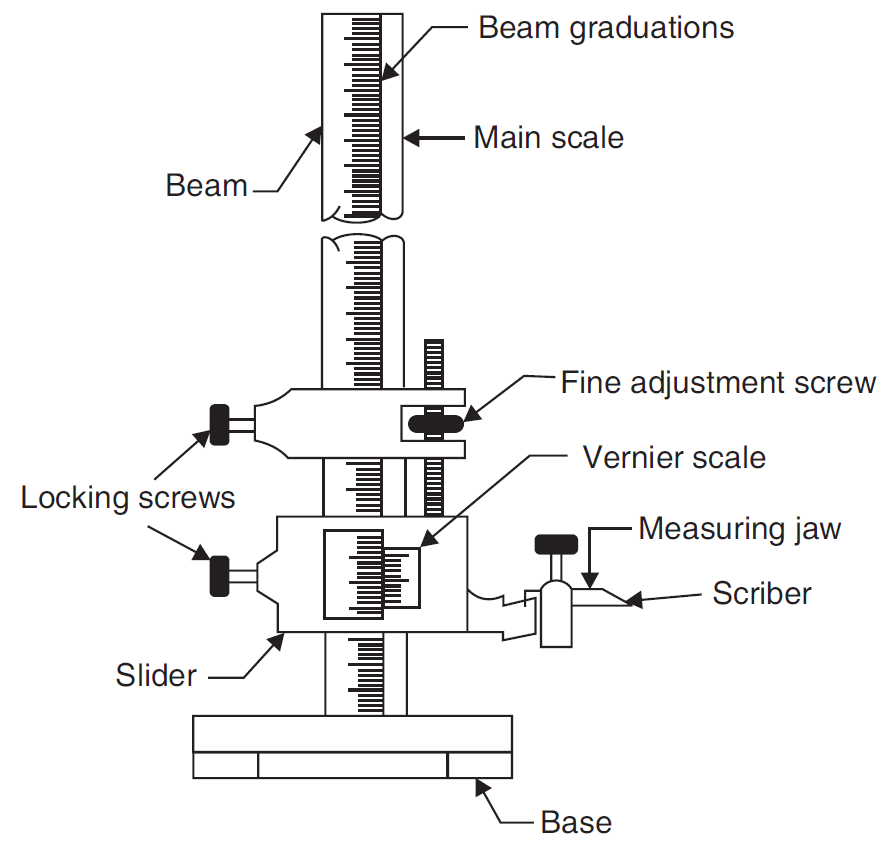

The instrument comprises several key components, each contributing to its functionality:

- Beam: A vertical column with graduations for measurement. It provides structural support and acts as the primary reference for readings.

- Main Scale: Marked along the beam, this scale provides coarse measurement readings.

- Vernier Scale: A smaller, movable scale attached to the slider. It allows for precise readings by comparing its divisions with those on the main scale.

- Slider: A movable part that carries the Vernier scale and measuring jaw. It can be adjusted up and down the beam.

- Measuring Jaw: Used to make contact with the object being measured, ensuring the height or distance is recorded.

- Fine Adjustment Screw: Allows for precise positioning of the slider and measuring jaw.

- Locking Screws: Secure the slider and fine adjustments in place after achieving the desired measurement.

- Scriber: A pointed tool, typically carbide-tipped, attached to the measuring jaw. It is used to scribe lines or mark precise points on a workpiece.

- Base: A flat, heavy foundation that ensures the instrument remains stable during use.

Least Count of a Vernier Height Gauge

The least count of a Vernier Height Gauge is the smallest measurement it can accurately read. It is calculated as:

Least Count = Smallest division on the main scale – Smallest division on the Vernier scale

For example, if the main scale has a division of 1 mm and the Vernier scale subdivides this into 50 equal parts, the least count is:

Least Count = 1 mm / 50 = 0.02 mm

This precision makes the Vernier Height Gauge an invaluable tool for applications requiring fine tolerances

Advantages of a Vernier Height Gauge

- High Accuracy: Enables precise measurements down to the least count of the instrument (e.g., 0.02 mm).

- Versatile Applications: Useful for scribing, height measurements, and layout marking.

- Durability: Constructed from robust materials such as stainless steel, making it long-lasting and suitable for industrial use.

- Ease of Use: The combination of the main scale and Vernier scale allows for intuitive measurement readings.

- Cost-Effective: Compared to advanced digital tools, Vernier Height Gauges are affordable while maintaining accuracy.

Applications of a Vernier Height Gauge

- Manufacturing: Measuring and marking precise heights during machining operations.

- Quality Control: Ensuring that components meet specified dimensions.

- Metalworking: Scribing lines for cutting, drilling, or welding.

- Tool and Die Making: Aligning and positioning parts with high precision.

- Laboratories: Conducting measurements and experiments requiring accuracy.

- Inspection: Verifying heights and distances in finished parts.

Disadvantages of a Vernier Height Gauge

- Manual Operation: Relies on human skill, which may introduce errors if not handled carefully.

- Time-Consuming: Reading the Vernier scale requires attention, making it slower compared to digital height gauges.

- Limited to Vertical Measurements: Designed solely for height and vertical dimensioning tasks.

- Potential for Wear: Frequent use can lead to wear on the graduations or mechanical parts, affecting accuracy.

- Requires Flat Surface: The instrument must be used on a perfectly flat base for precise measurements.

Conclusion

The Vernier Height Gauge remains an essential tool in engineering and manufacturing due to its reliability, precision, and affordability. While digital alternatives offer faster readings, the Vernier Height Gauge continues to be valued for its simplicity and accuracy in a wide range of applications. Understanding its working principle, components, and proper usage ensures that it remains a cornerstone of precision measurement tools. Despite some limitations, its versatility and practicality make it indispensable in industrial and laboratory settings.